Across the globe, power generation plants have long produced and supplied electricity to homes, schools, hospitals, and businesses. Whether it’s the refrigerator in your kitchen or the cellphone in your pocket, if it needs power, there’s a plant working tirelessly behind the scenes to supply the energy that keeps it running.

But more of these plants are needed as the world’s use of electricity reaches new heights. Demand continues to surge despite ongoing economic uncertainties.

This surge is driven in large part by rapid growth in energy-intensive sectors—especially data centers—as the rise of artificial intelligence, cloud computing, and large-scale digital infrastructure pushes operators to expand capacity faster than ever before.

“Energy is the engine of economic growth.”

— World Bank

Intense heat, elevated pressures, and exposure to hazardous chemicals create a challenging environment within power plants, be they natural gas, combined cycle, nuclear, hydroelectric, geothermal, or renewable facilities. To operate reliably, they depend on equipment engineered for durability and performance. Flexible metal hoses play a critical role in this equation, helping maintain system integrity and uptime so plants can continue powering every aspect of daily life.

Why Choose Metal Hose for Power Generation Piping

Metal hoses are a critical component in power generation operations for several key reasons, starting with their ability to withstand extreme heat.

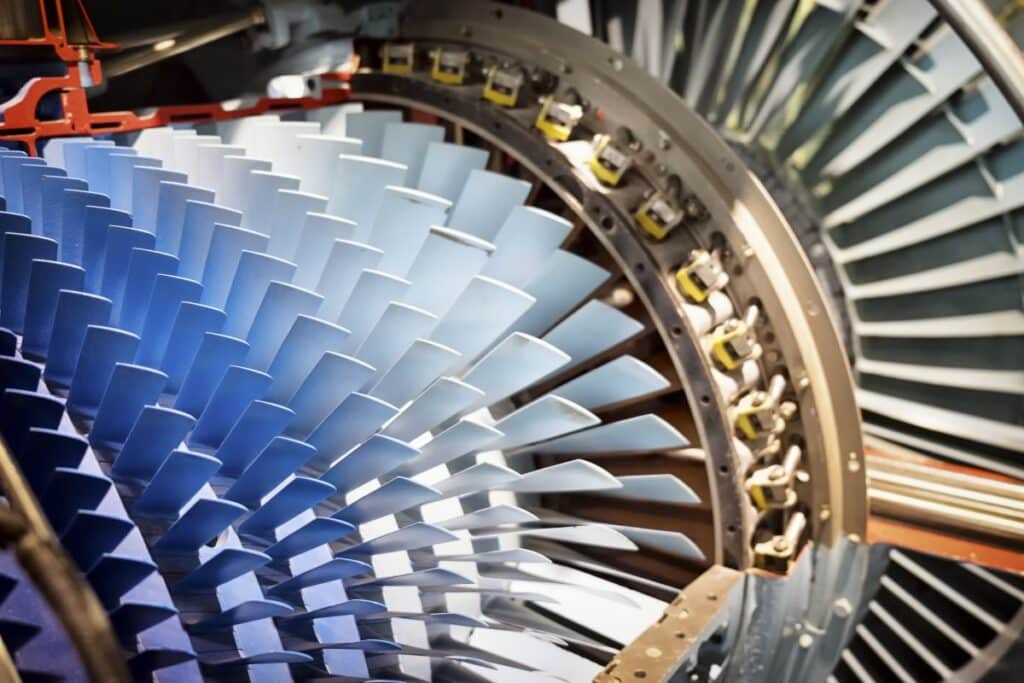

Burners and boilers operate around the clock to produce the steam that drives turbines, a process that involves temperatures reaching thousands of degrees Fahrenheit. Metal hoses play an essential role, safely delivering fuel gases to the burners, transporting steam from the boilers to the turbines, and removing exhaust gases from the facility.

Frequent cycling further challenges equipment. With each start-up and shutdown, temperature changes, pressure fluctuates, and vibrations introduce stress into the piping system. Flexible metal hoses for power generation applications are engineered to absorb this movement, reducing strain on surrounding components and helping to prevent damage or failure, demonstrating reliability in environments where lesser components fail.

Longevity is a major advantage of metal hoses. Power generation facilities are typically inspected every 8,000 hours, with major overhauls occurring at 24,000 hours. High-quality metal hoses can last up to 30,000 hours — meaning they won’t be the weak link in a facility’s maintenance schedule.

The Metal Advantage in Power Generation

Power generation systems push components to their limits with extreme heat, high pressure, constant vibration, and exposure to aggressive chemicals. In these conditions, rubber and plastic hoses degrade quickly. They can crack, blister, or lose structural integrity, often leading to premature failure.

What’s more, non-metal hoses are inherently permeable. This means even before visible damage occurs, gases can pass through the hose wall. In the case of natural gas and other flammable media, even small leaks can pose serious risks ranging from nausea and dizziness at low concentrations to explosions, environmental damage, and fatal outcomes at higher levels.

By contrast, metal hoses offer unmatched performance and safety. They are:

- Non-permeable: No risk of gas seepage through the hose wall

- Fire-resistant: Suitable for use near ignition sources or high-heat surfaces

- Highly durable: Built to withstand vibration, abrasion, and mechanical stress

- Corrosion-resistant: Compatible with a wide range of flow media

- High temperature performance: Rated for service at temperatures up to 1500°F, with Inconel 625 options for applications up to 1,800°F

In short, metal hoses and expansion joints are the safest and most reliable solution for power generation piping applications. Their strength and stability reduce the risk of hazardous leaks, unplanned downtime, and costly equipment failures, delivering long-term performance under demanding operating conditions.

How Penflex Supports Power Generation Applications

Power generation systems demand piping solutions that perform reliably in the face of elevated temperatures, high pressures, and constant vibration. Here’s how our metal hose designs meet those challenges head-on:

High pressure ratings: When corrugated hoses are pressurized, the material expands. Braid functions like a restraining cage, preventing the hose from elongating or swelling and, thus, acts as the pressure carrier. Depending on size, wall thickness, and hose series, Penflex hoses can reach working pressures up to 5,000 PSI.

High operating temperatures: Our stainless steel hoses are rated for continuous service up to 1,500°F. However, once temperatures exceed 1,000°F, derating factors fall quickly and maximum working pressures must be reduced accordingly. For especially high-temperature applications, we can offer specialized thermal barriers, ceramic coatings, or hoses made from Inconel 625. Known for its exceptional strength at elevated temperatures, Inconel 625 performs reliably in environments up to 1,800°F.

Corrosion resistance: Our power generation hoses are built to safely handle the harshest chemicals, including ammonia, sulfuric acid, and hydrochloric acid, used to generate electricity. Our thick-walled power generation assemblies offer unmatched corrosion resistance, cutting the risk of frequent replacements, mechanical failures, and costly shutdowns.

Size range: From ¼” to 24”, Penflex’s flexible metal hoses come in a range of sizes that can be seamlessly integrated into any configuration or space.

Code compliance: While all of our hoses are manufactured in line with industry standards, we can also design hoses to be compliant with other standards, including ASME B31.1 and B31.3, per customer specification. Compliance ensures our hoses deliver the highest levels of quality, safety, and reliability.

Quality welds: High-quality welds are essential to hose integrity and long-term performance, especially in power generation facilities. At Penflex, we achieve this through a proven process that includes TIG welding and argon purging, which together produce clean, strong welds without compromising corrosion resistance. Our team includes ASME Section IX–certified welders, on-site certified welding instructors, and non-destructive examination (NDE) specialists, ensuring every assembly is tested and leak-tight before it leaves our facility.

Leak testing: Each metal hose for power generation undergoes air-under-water testing and, if specified, hydrostatic testing. Other more acute leak testing methods, such as helium mass spectrometer testing, are available to customers per request.

Tagging: Each hose assembly is fitted with a tag displaying key information, such as the date of manufacture and leak test results, to support preventative maintenance planning and scheduled replacement based on expected service life.

Penflex Expansion Joints for Power Generation Facilities

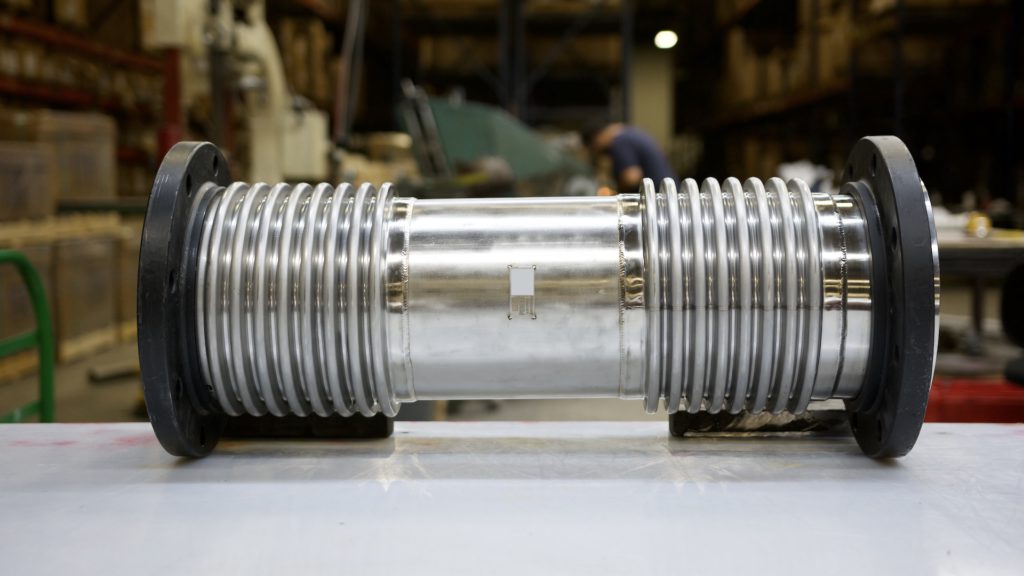

For applications where there is axial movement, aggressive materials that require an uncommon alloy, or simply no space to accommodate a metal hose, we offer a line of expansion joints for power plants. These components, designed in accordance with EJMA, ASME B31.1, or ASME B31.3 per customer specifications, keep systems operating reliably under the most challenging conditions.

Here are the key features of our expansion joints:

Sizes: Our expansion joints are available in sizes 2.5” through 40,” with options for tooling up to 120”.

Bellows: To further accommodate movement and distribute stress more evenly, we offer multi-ply bellows. They are engineered to maximize cycle life under the demanding conditions found in power generation environments.

Wide variety of expansion joints: We offer a variety of expansion joints, including externally-pressurized expansion joints, in-line pressure balance joints, hinged expansion joints, single joints, and universal joints.

Attachments: To strengthen connections and simplify installment, we offer multiple attachments for our expansion joints, including fixed flanges, floating flanges (Vanstone), R flanges, and weld nipples.

Non-destructive examination: From pressure testing and liquid penetrant testing to fluorescent penetrant testing and radiography, we offer multiple testing methods to ensure each product can perform reliably under the extreme conditions found in power generation facilities.

Recommended Products for Power Generation Applications

P4 Series

Made in accordance with ISO 10380, P4 is a general purpose industrial hose.

P5 Series

Large diameter hose options for power generation applications.

Expansion Joints

To accommodate the thermal expansion and irregular, consistent movements in gas turbine systems, expansion joints need to be designed for extreme operating conditions.

Beyond the Product: The Penflex Partnership

At Penflex, we see every order as an opportunity to continue building our relationship with a current customer–or the beginning of a partnership with a new customer. Our customers count on us not only for a quality product, but also for expertise, responsive service, and resources to help them get the most out of their investment.

Dedicated Engineering Support

Our sales engineers work closely with you from project prototype through delivery, helping define requirements for new products and replacements. A dedicated account manager means you have a single point of contact who understands your business and responds quickly with thoughtful solutions.

Practical Technical Resources

From online calculators and engineering bulletins to in-person and virtual training, we give your team the tools to make informed decisions and the confidence to install, operate, and maintain hoses for maximum longevity.

Full Quality Documentation

On request, we provide complete record packs—including material test reports, leak and pressure test results, and cleaning procedure documentation—so you can meet compliance requirements and maintain full traceability.

Our commitment to service is reflected in our 99% customer retention rate and an average customer relationship of 20 years. We aim to make every interaction count, combining technical know-how with the kind of service that turns first-time buyers into long-time partners.