The Semiconductor Manufacturing Industry Landscape

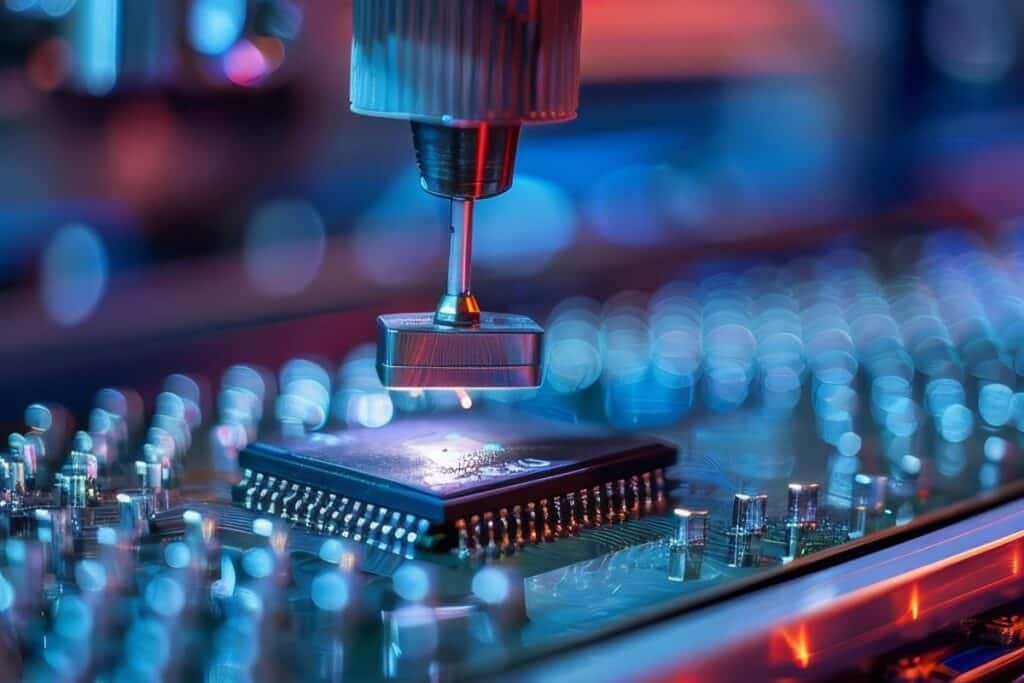

From the smartphones in our pockets to the satellites orbiting Earth, semiconductors power nearly every piece of technology we depend on. These chips are not just fundamental to modern life, they’re actively reshaping how we live, work, and connect.

Surging demand from AI workloads, cloud data centers, EV platforms, and high-end consumer electronics is pushing the semiconductor manufacturing industry to expand at a record pace. Each leap in chip performance unlocks new applications—and those applications, in turn, drive the next wave of chip demand, advancing a cycle of compound growth that shows no signs of slowing.

To keep pace, an estimated $1 trillion dollars is expected to be invested in new fabrication plants (fabs) by 2030. [1]

As fabs expand capacity and semiconductor equipment manufacturers introduce more advanced process tools, OEMs and subsystem suppliers are under pressure to deliver components that meet strict standards for cleanliness and provide proven reliability in mission-critical environments.

Even microscopic impurities can degrade performance, reduce yields, or damage equipment. And because many of the gases used in chipmaking are highly corrosive and toxic, every component involved in their transport must be designed for purity, safety, and system integrity.

Metal Hose in Semiconductor Manufacturing Equipment

Metal hoses play a vital role within semiconductor manufacturing equipment. Their combination of cleanliness, flexibility, corrosion resistance, and high-temperature performance makes them an ideal solution wherever movement and needs for purity and reliability intersect.

Ultrapure Gas Delivery Systems

Metal hoses are the clean, leak-tight choice for transferring the ultrapure gases used in chipmaking. Their non-permeable stainless steel construction eliminates concerns around outgassing and permeation for semiconductor equipment manufactures and fab operators. Easily cleaned to customer specifications and, when capped and packaged to maintain cleanliness during shipment, metal hoses help ensure gas purity and process consistency.

Highly corrosive gases will degrade hose material over time. With superior corrosion resistance, metal hoses often last longer than polymer alternatives in many applications, helping maximize uptime in “always-on” fabs.

Thermal Management and Semiconductor Cooling Subsystems

Semiconductor etching and other plasma processes generate significant heat during wafer processing. Stainless steel flex hoses withstand the elevated temperatures and thermal cycling associated with both etch tools and cooling systems, enabling efficient heat removal while preserving equipment uptime. Their flexibility also supports tight-radius routing within compact enclosures where rigid piping cannot accommodate movement or expansion. By maintaining consistent thermal control, they help protect sensitive components and ensure stable process performance.

Cleanrooms and Contamination Control Expectations

Semiconductor cleanroom environments maintain strict limits on particulate, moisture, hydrocarbons, internal residues, and surface condition—down to microscopic levels—because even trace contaminants can affect yield and process stability. These requirements extend into every subsystem, including flexible connections responsible for delivering and removing gases and fluids inside process tools. This is where design and manufacturing methods make a measurable difference.

Why is Metal Superior to Other Materials Used in Semiconductor Manufacturing?

Teflon (PTFE) hoses are commonly found in semiconductor fabs, but many manufacturers are shifting away from them due to concerns around forever chemicals, known as per- and polyfluoroalkyl substances (PFAS).

Beyond these concerns, PTFE and rubber hoses are inherently porous, allowing gas permeation that can create safety risks, equipment contamination, and costly loss of process gases. These materials also degrade faster, both in use and in storage, and can shed particulates into critical gas lines.

Metal hoses, by contrast, are non-porous, PFAS-free, and far more resistant to heat and chemical attack, resulting in longer service life and more reliable performance inside fabs.

Why Semiconductor Equipment Manufacturers Choose Penflex

Semiconductor equipment OEMs look for subsystem partners who understand high-purity process requirements and can deliver components that protect yield, maintain uptime, and perform reliably under continuous operation. Penflex metal hose assemblies are engineered to meet the industry’s most demanding expectations for cleanliness, corrosion resistance, flexibility, and leak integrity, making us a trusted supplier for mission-critical gas and fluid handling connections.

Clean ID technology: Penflex’s Clean ID hose is manufactured without internal tooling, lubricants, or forming fluid, resulting in a product free of the grease, moisture, oil, and particulate typically left behind by conventional manufacturing methods. The result is a truly clean inside diameter that preserves gas integrity and supports consistent process performance.

Alloy selection: Penflex offers a variety of alloys for safe handling of the specialized gases and chemicals used in semiconductor manufacturing, including hydrogen fluoride, tungsten hexafluoride, sulfur hexafluoride, and nitrogen trifluoride. Our 316L and 321 stainless steel hoses are preferred, but in the most aggressive applications, hoses made from Hastelloy C-276 or Inconel 625 may be better options.

Non-porous material: Semiconductor process gases can lose their effectiveness when exposed to even trace amounts of contamination, altering their chemical composition. Non-porous by nature, metal hoses create a secure barrier that prevents gas from permeating the hose wall and keeps external contaminants from entering the system.

Corrosion resistance: All hoses are prone to deterioration if they’re continuously exposed to harsh substances and intense heat or pressures, but our austenitic stainless steel hoses have superior corrosion resistance. Their compatibility with fluorine-containing gases, aggressive etching chemicals, and cleaning and surface treatment substances means users can expect a longer lifespan than what is achievable with other materials.

Increased flexibility: Penflex’s compressed-pitch hose designs deliver superior flexibility, simplifying installation in tight or hard-to-reach spaces, an advantage in semiconductor cleanroom environments with compact layouts.

Quality welds: High-quality welds are essential to hose integrity and long-term performance, especially in fabs. At Penflex, we achieve this through a proven process that includes TIG welding and argon purging, which together produce clean, strong welds without compromising corrosion resistance. Our team includes ASME Section IX–certified welders, on-site certified welding instructors, and non-destructive examination (NDE) specialists, ensuring every assembly is tested and leak-tight before it leaves our facility.

Leak testing: Each hose destined for the semiconductor manufacturing industry undergoes our standard air under water test, though more sensitive leak testing methods are often used. Our most acute leak testing method, helium mass spectrometry, detects leaks as small as 10-12 cubic centimeters per second!

Superior cleanliness: In addition to our Clean ID options, we can accommodate customer-specified cleaning procedures—including oxygen cleaning services—upon request. To maintain cleanliness, all assemblies are individually bagged after preparation.

Supporting EPC/MEP Teams in Semiconductor Fab Construction

In addition to supplying reliable components for process tools, Penflex partners with engineering firms and construction teams during fab build-out. EPC and MEP providers must integrate process equipment, facility utilities, and cleanroom requirements into a cohesive, high-purity environment. It’s a complex task, and fluid conveyance is not always a core discipline within these firms.

Many rely on suppliers, like Penflex, to provide products, services, and knowledge in specialized areas. For a successful semiconductor fab construction project, engineering and construction firms rely on suppliers who can augment their offering while providing consistent documentation, traceability and installation guidance.

Recommended Products for Semiconductor Equipment Manufacturers

Clean ID

Designed for high purity gas delivery applications, Clean ID features a truly clean inside hose diameter.

P5 Series

Large diameter hose options for HVAC applications within semiconductor fabs.

Exhaust Hose

Interlocked construction for exhaust applications focused on heat removal.

Penflex: Partner to the Semiconductor Manufacturing Industry

At Penflex, we see every order as an opportunity to continue building our relationship with a current customer–or the beginning of a partnership with a new customer. Our customers count on us not only for a quality product, but also for expertise, responsive service, and resources to help them get the most out of their investment.

If your team is designing new process equipment or supporting semiconductor fab construction, our engineering group can review requirements, develop prototypes, and provide documentation aligned to cleanroom and reliability standards.

Dedicated Engineering Support

Our sales engineers work closely with you from project prototype through delivery, helping define requirements for new products and replacements. A dedicated account manager means you have a single point of contact who understands your business and responds quickly with thoughtful solutions.

Practical Technical Resources

From online calculators and engineering bulletins to in-person and virtual training, we give your team the tools to make informed decisions and the confidence to install, operate, and maintain hoses for maximum longevity.

Full Quality Documentation

On request, we provide complete record packs—including material test reports, leak and pressure test results, and cleaning procedure documentation—so you can meet compliance requirements and maintain full traceability.

Our commitment to service is reflected in our 99% customer retention rate and an average customer relationship of 20 years. We aim to make every interaction count, combining technical know-how with the kind of service that turns first-time buyers into long-time partners.

Footnotes

[1] McKinsey & Company. Semiconductors have a big opportunity—but barriers to scale remain. Retrieved November 17, 2025 from https://www.mckinsey.com/industries/semiconductors/our-insights/semiconductors-have-a-big-opportunity-but-barriers-to-scale-remain.