Why Engineers Choose Inconel® 625 for Demanding Hose Applications

The 300 series austenitic stainless steels offer excellent corrosion resistance and their operating temperature ranges far exceed those of other common hose materials like EPDM, Teflon and PVC. However, even these high performance hose materials have limitations.

Consider environments where temperatures climb above 1000°F–such as the “hot sections” of gas turbines—or where aggressive chemicals like hydrochloric acid and anhydrous ammonia are present.

In applications like these, engineers turn to special alloys like Inconel 625, a material valued for its exceptional high-temperature strength and corrosion resistance.

Material Profile: What is Inconel 625?

Inconel 625 is a nickel-chromium alloy developed by INCO (now Special Metals) in the early 1960s. While nickel and chromium define Inco 625, key alloying elements molybdenum and niobium further support corrosion resistance while also contributing to Inconel’s signature high-temperature strength.

Where are Inco 625 Flex Connectors Used?

Inconel 625 hoses are found in the aerospace, chemical processing, power generation and steelmaking industries in applications involving engine systems, reactors and certain aggressive media.

The alloy is unique in its ability to resist corrosion from both oxidizing and reducing acids, a sampling of which includes:

- Alkalies and salt

- Hydrochloric acid

- Hydrofluoric acid

- Nitric acid

- Organic acids

- Phosphoric acid

- Sulfuric acid

Inconel 625 vs. 300 Series Stainless Steels

Despite the advantages of Inco 625 over the 300 series stainless steels, the higher costs associated with this “special” alloy deter some metal hose buyers. While there is no need to over-engineer a component because–many times–a stainless steel hose will work, there are other times it won’t. It’s good to know when Inconel is worth the premium.

One scenario involves elevated temperatures. Inconel 625 has a maximum service temperature of 1800°F. Compare this to the 1000°F practical limit for stainless steel, and it’s easy to see why Inconel is used in rocket launch systems!

The direct relationship between temperature and pressure also means Inconel 625 hoses maintain their pressure carrying capacity better than 321 or 316L hoses (with 304L braid) as temperatures climb. Reviewing temperature derating factors for these alloys illustrates the point.

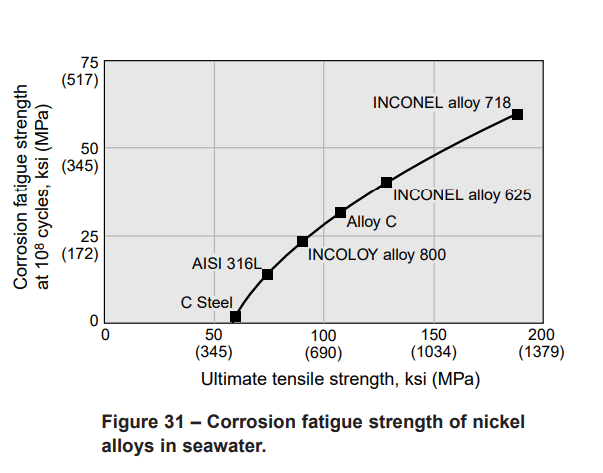

The other major scenario involves corrosion resistance. Inconel 625 significantly outperforms 304, 321, and 316L in aggressive media applications—particularly those involving chlorides. The 300 series stainless steels are vulnerable to pitting corrosion in chloride-rich environments. Inconel 625, in contrast, was designed to better resist pitting corrosion and other forms of local attack such as crevice corrosion, as well as chloride-ion stress corrosion cracking.

The chart below, sourced from Special Metals’ High-Performance Alloys for Resistance to Aqueous Corrosion, shows how these materials fare in seawater service with Inconel 625 significantly outperforming 316L.

Material Selection in Chlorine and Chloride Applications

Inconel 625 is not the only alternative to the 300 series stainless steels. There are other special alloys and often, to make a decision, engineers reference Pitting Resistance Equivalent Numbers (PREN). Based on a material’s chromium, molybdenum and nitrogen content, PREN is an assessment of how well an alloy resists pitting corrosion.

Inconel 625 has a PREN more than double that of 316L underscoring its superior ability to withstand corrosion in chloride applications. But Hastelloy® C-276 has an even higher PREN.

While absent from the table above–because it contains no chromium, molybdenum or nitrogen–Monel® 400 is commonly used in seawater applications. However, Monel’s corrosion resistance is second to that of the nickel-chromium alloys.

Inconel 625 vs. Hastelloy C-276

While the potential list of chloride-containing media is long, it is important to remember that alloy selection depends on a myriad of factors not limited to media, or mix of media. Piping engineers must also consider concentration, aeration and contaminants, as well as other materials in the piping system. Cost and availability carry weight too.

Hastelloy C-276 will not always be the best option even if, speaking generally, it offers the greatest level of corrosion resistance across a broader swath of media.

Consider temperature again. Inconel’s high-temperature strength is an advantage over Hastelloy as well. We consider the practical limit of Hastelloy C-276 to be 800°F. Also note the differences in derating factors as temperatures climb, something to review in higher pressure applications.

Making Inconel 625 Hoses: Consider Welder Skill and Experience

Welding sheet metal demands great skill. The level of precision required is immense–for instance, consider ¼” P3. The material is a mere .006” thick!

All Penflex welders are certified to the industry’s highest standard ASME Section IX, but to weld special metals like Inconel 625, Monel 400 and Hastelloy C-276, they must have at least one year of experience welding stainless steel hoses.

While the processes and techniques are the same whether welding Inconel-to-Inconel or stainless-to-stainless, there is less room for error. The special alloys are unforgiving and, as a result, weld discontinuities and leaks are more common. Welders must consistently deliver to a greater degree of precision and the ability to do so often comes down to more than training: experience.

Inconel 625 Hose Assemblies from Penflex

Penflex is one of the few US hose manufactures to stock Inconel 625 (UNS N06625) hose and braid, in sizes ¼” – 8”, and employ welders trained and experienced in making assemblies with this exacting material.

When the 300 series stainless steels won’t cut it, Inconel 625 offers longer service life in many high temperature and/or corrosive applications. If you’re dealing with hoses in a challenging environment, reach out to talk to an engineer about your application.