Should you use a metal or rubber pump connector for your application?

Pump connectors play an important role in protecting hard pipe and equipment from the movement, vibration, and noise generated by pumps and compressors. But when it comes to choosing between a metal or rubber pump connector, the decision depends on the specific needs of your application.

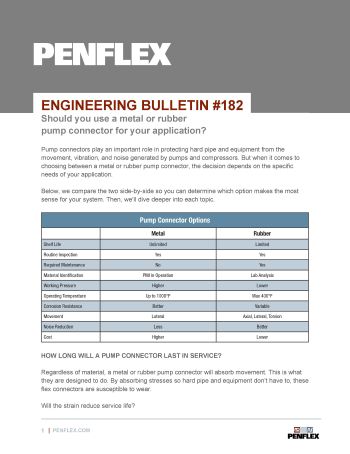

Below, we compare the two side-by-side so you can determine which option makes the most sense for your system. Then, we’ll dive deeper into each topic.

How long will a pump connector last in service?

Regardless of material, a metal or rubber pump connector will absorb movement. This is what they are designed to do. By absorbing stresses so hard pipe and equipment don’t have to, these flex connectors are susceptible to wear.

Will the strain reduce service life?

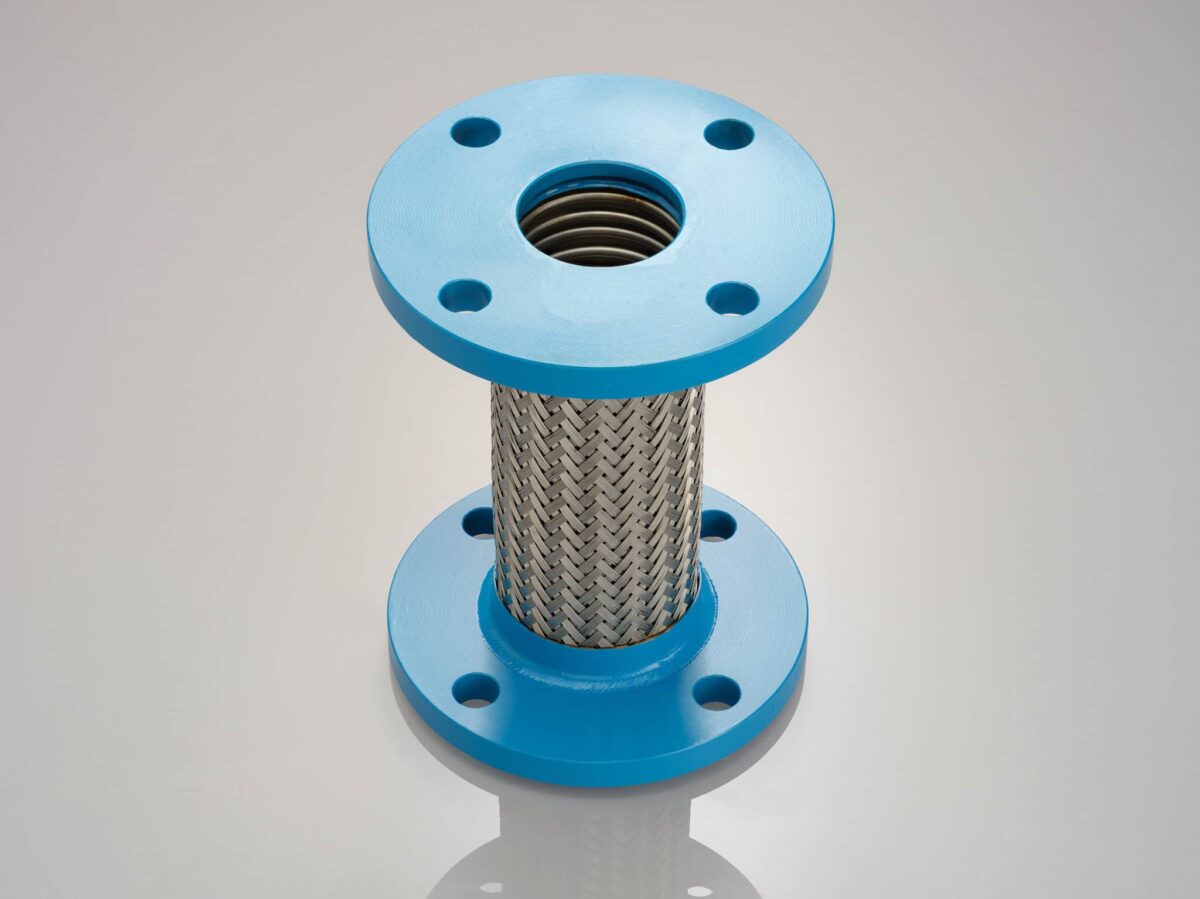

With a metal pump connector, the answer is no. We’re talking about some pretty robust materials here. Let’s look at what is used to fabricate a standard flanged pump connector.

- 304/321/316L hose

- 304L/316L braid

- Carbon steel plate flanges

If installed properly and operating within design limits, a metal pump connector can, theoretically, last indefinitely.

In either scenario, improper installation or operation outside design limits will necessitate replacement sooner.

(PFPC-032)

With a rubber pump connector–or rubber expansion joint as they are more often called–the answer is yes. Rubber does not have the same fatigue strength that metal does. On average, a rubber expansion joint will last 5-15 years in service. If operating in a critical application, it is likely replacements will be required more often.

Do pump connectors have a shelf life?

Due to material degradation over time, rubber expansion joints come with a shelf life, making this an important consideration for stocking programs. Shelf life is based on the date of manufacture. The longer a part sits on the shelf—especially if it isn’t stored properly—the shorter service life will be. This is not a concern with metal pump connectors which can be stored indefinitely without impacting performance.

What kind of maintenance is required?

Routine inspections are a good preventative maintenance practice for any piping system.

For metal pump connectors, users should look for:

- Broken, bulged, loose or worn braid

- Dents or flat spots

- Loose or cracked end fittings

- Twisting of the braid

For rubber expansion joints, users should look for:

- Blistering or further indication of ply separation

- Change in material texture

- Cracking

- Flattening of the arch

If users see any of the items listed above, further investigation and possible replacement may be required. Of course, action should be taken immediately if any leaks or visible signs of corrosion are noted regardless of whether a metal or rubber pump connector is installed.

Regular maintenance is, however, only a requirement for rubber expansion joints. These components need routine cleaning to remove buildup of dirt, oil, and chemical residue that can degrade elastomeric materials. Conditioning may also be required to prevent the rubber from drying out and cracking. On the other hand, metal pump connectors do not require this kind of ongoing maintenance.

What role do pressure and temperature play in material selection?

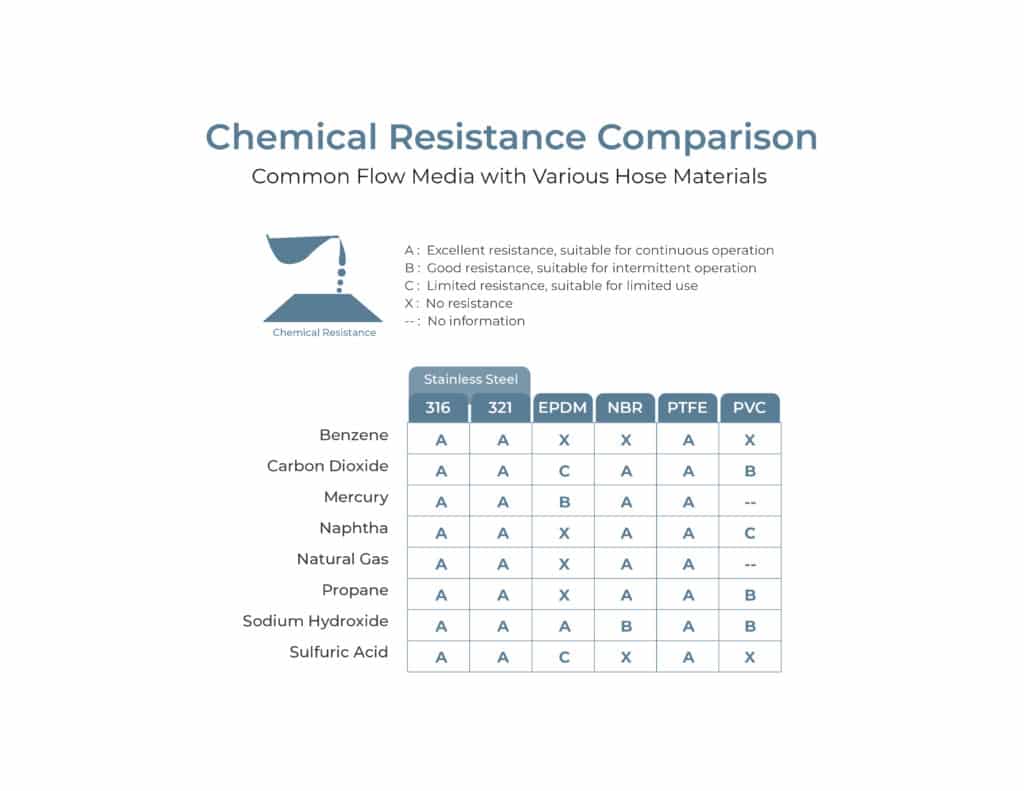

And as a rule, metal components can operate within a wider temperature range. Just reference the chart below to see how stainless steel accommodates a greater range of temperatures than common elastomer materials NBR and EPDM.

Are you working with a high pressure pump? Or saturated steam? In a high pressure or high temperature application, a flexible piping component’s strength is critical. Generally, metal pump connectors have higher pressure ratings than comparable rubber pump connectors.

Over time, heat accelerates the aging process of rubber. Materials harden and become stiff. Components are then susceptible to cracking and less capable of absorbing the movements they were designed to absorb.

Even in the short term, as temperatures climb above 70°F there is an impact on material strength. This is true of metal as well, though not to the same degree. As a result, working pressures must be reduced in elevated temperature applications. Users can consult derating factors published by manufacturers of both metal and rubber pump connectors for specifics.

Given metal retains its material properties better than other materials at elevated temperatures, it is often the material of choice in high temperature applications.

Is flow media corrosive?

Chemical resistance charts indicate that stainless steels generally provide broader compatibility across a wider range of chemicals than most rubber materials. However, advances in polymer technology continue to expand the range of applications where elastomeric expansion joints may be suitable.

Material selection should always consider flow media. In systems that circulate corrosive fluids—for instance, many refrigerants used in cooling applications are corrosive–metal pump connectors often offer superior long-term performance. In contrast, water-based systems typically pose less of a corrosion risk, allowing for greater flexibility in material choice.

What kind of movement do you need to accommodate?

Pump connectors are designed to absorb movement in a piping system, but not all connectors handle movement the same way.

Metal pump connectors are designed to accommodate lateral movement and some piping misalignment. The amount of movement will be determined, in large part, by the length of the component. Like any other metal hose assemblies, pump connectors are not designed to accommodate axial or torsional movements.

Rubber pump connectors, on the other hand, can accommodate axial, lateral, and even some torsional movement, often to a greater degree than metal given their elastic properties. They can also be used to correct some piping misalignment. Another advantage of rubber expansion joints is their ability to absorb multiple kinds of movement simultaneously. For these reasons, rubber connectors are often preferred when the pump base is mounted on a spring.

Is your primary objective to reduce noise?

If a quieter system is the goal, rubber pump connectors have a clear advantage. Their flexibility allows them to absorb vibration and dampen sound more effectively than metal pump connectors, making them a popular choice for mechanical rooms located near offices, apartments, and other occupied spaces.

Metal pump connectors, while excellent at handling certain operating conditions, are not designed with noise reduction in mind. They may absorb some vibration by virtue of being a flexible component, but the effect is minimal compared to rubber. In noise-sensitive environments, that difference can be important—not just for comfort, but for compliance with sound-level regulations in certain facilities as well.

How much are you looking to spend on a pump connector?

Budget is always part of the conversation, and the choice between a metal or rubber pump connector will affect the bottom line. Metal pump connectors generally come with a higher price tag, reflecting the higher cost of materials and labor. Rubber pump connectors, on the other hand, are typically less expensive up front, which can make them appealing for projects with tight budgets or in applications where durability is less of a priority.

While the initial investment in metal can pay off over time through reduced maintenance and replacement costs, rubber may make more sense for short-term or less demanding applications.

Selecting the best fit for your system

Selecting between a metal or rubber pump connector starts with understanding the demands of your application. High temperatures, corrosive media, or a need for long-term, maintenance-free performance often point to metal. Noise-sensitive environments, greater movement flexibility, or budget constraints may lead you toward rubber. In many cases, it’s not about which is “better” in a general sense, but which is better for your system.

Penflex stocks a full range of metal pump connectors in both flanged and threaded configurations for quick shipment. If you’re weighing your options or need guidance on the right connector for your application, our engineering team is ready to help.

If your application requires a configuration not listed among our stock pump connectors, reach out to one of our engineers for a custom assembly quote.