Braid is the primary pressure carrying element in a metal hose assembly and plays a central role in determining pressure ratings. Pressurize a hose beyond its unbraided pressure carrying capacity, and it will elongate. Its corrugations will deform, and this constitutes failure. Add braid, and the hose is restrained, allowing it to maintain its shape and operate at higher working pressures.

Metal hosers know that adding additional layers of braid or using a heavier—or “stronger” braid—can increase working pressure, but there are limits to what is achievable.

In this engineering bulletin, we’ll explore the key design variables that influence metal hose pressure ratings, including:

- Braid construction, including:

- Braid angle

- Tensile strength of wire

- Number of braid layers

- Relationship between braid and hose designs

Braid Construction and Working Pressures

Let’s take a look at the components of braid construction to see how each design choice influences pressure ratings. As an example, the braid construction for Penflex 1” P3 (P3-H30xx-B30xx-016) is 48 x 7 x 0.14, where:

- 48 = number of braid carriers (components holding a bobbin or spool of wire)

- 7 = number of wires on each carrier

- .014 = braid wire diameter in inches

All else remaining equal, increasing carrier count, wires per carrier, or braid wire diameter will increase the braid’s theoretical burst pressure. It will not, however, guarantee a higher published working pressure.

Not Published, but No Less Important: Braid Angle and Wire Tensile

Less often discussed, but no less important, elements of braid construction are:

- Braid angle: Acute angle formed by braid strands and longitudinal axis of hose. (Other manufacturers may calculate braid angle based on the lateral axis. This is an important distinction to be aware of.)

- Tensile strength of wire: A metal wire’s ability to resist tension, or the forces that elongate it.

Which Part of the Braid Angle Matters

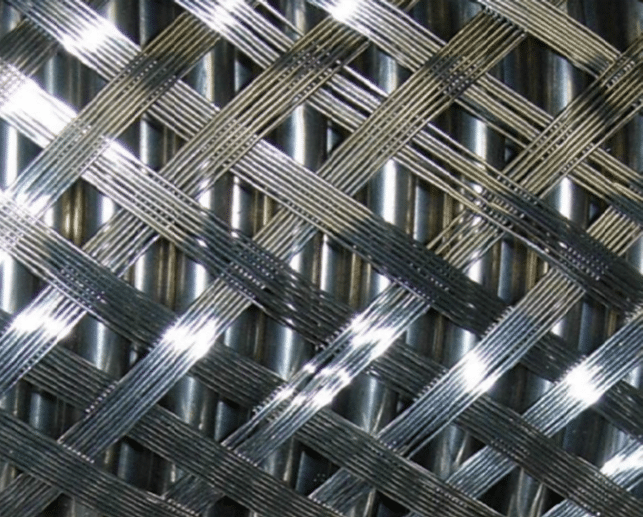

The relationship between braid and pressure ratings would be much more straightforward if braid wires lay horizontally on a hose, parallel to the longitudinal axis. However the braid wouldn’t be nearly as effective at handling movement if they were. Instead, the crisscross pattern delivers a solution (a braided sheath) that can bend and flex with the hose beneath without losing its shape and accompanying pressure carrying capacity.

Only the axial part of the braid angle is pressure bearing. The more acute the angle—or the closer the angle is to the longitudinal axis—the greater the pressure carrying capacity will be. For this reason, it’s critical to understand which side of the braid angle is being referenced in published specifications.

If a manufacturer offers braid with a 38° angle, but this represents the perpendicular angle, then the angle of the braid that actually impacts pressure rating is 52°. This would not be as conducive to higher working pressures.

Because braid angle directly influences pressure capacity, design changes intended to strengthen the braid, such as adding wires, could unintentionally reduce pressure ratings if they shift the braid angle away from the longitudinal axis.

Limitations of Increasing Wire Tensile

A wire with more tensile strength will be stronger and support higher pressure ratings. However, if increasing tensile means there’s an increase in wire diameter, then again braid angle could be affected.

It’s a very nuanced conversation with many competing inputs! Our Pressure Calculator allows you to play around with changing those inputs to see the impact on theoretical burst pressure.

Generally speaking, when we refer to a heavier braid—let’s say Penflex’s 1SHB (800 Series) vs. 1SB (700 Series and P5 Series)—we could mean any, or many, of these inputs have been changed to deliver higher working pressures.

Are Higher Metal Hose Pressure Ratings Achievable with Braided Braid?

Braid can be categorized as plain braid weave or braided braid. In a plain braid, the wires are organized in a side-by-side formation, creating a carrier band. For braided-braid, individual wires are braided together to create carrier strands.

The braided wire formation helps prevent tangling of strands when fabricating braid for larger diameter hoses. Just imagine the surface area of a 22” hose—it’s significant and requires a lot of braid wires for adequate coverage!

Braided braid constructions are often assumed to increase pressure ratings due to their heavier appearance, but their primary role is organizational rather than structural.

All braided braids are made on our 96-carrier braid machine. These are used on some of Penflex’s 6” hose and all our hoses 8” and above. A braided braid construction is represented with parentheses around the last two numbers in the braid code. For instance, 721-1SB-256 has a braid construction of 96 x (29 x 0.025) where those bands of 29 wires, each with 0.025” diameter, are braided together to create a band before 96 of those bands are braided onto the hose.

Is Higher Coverage Braid Better?

The intersection of braid construction and hose surface area will determine how much of the hose is covered by braid. We call this braid coverage, and it can be either low or high.

Low coverage braid has visible diamond openings along the braid. These openings also expose the core beneath, making it susceptible to external damage or corrosion. High coverage braid has much smaller openings along the braid. The higher coverage also protects the core from any potential external damages.

While higher coverage braids may be associated with higher working pressures, this isn’t a helpful association. It’s important to remember that it’s the five factors discussed above that determine working pressures. These factors also determine braid coverage, thus coverage is a result of design choices, not a determinant of working pressure.

100% braid coverage would actually be bad design. Picture a hose bending. Can you see how the corrugations spread out on the top and scrunch together on the bottom? You need gaps in braid coverage for the wires to be able to reposition themselves in movement as well as when pressurized. 100% coverage, even very high coverages on certain hose designs, will restrict movement and should the hose flex, the braid wires will kink.

This may be a departure for hosers who cut their teeth with braided Teflon and other polymer-based hoses. There are different considerations with these hose materials, and braid coverage is a more important topic.

The metal hose industry has evolved to find higher coverage braids more aesthetically pleasing over the last few decades. While there is some truth to the notion of the braid as protection from abrasion, cosmetic preferences are a primary reason for differences between low and high coverage braids.

Impact of Additional Braid Layers on Pressure Ratings

When working with high pressure applications, additional braid layers may be needed to satisfy a working pressure requirement. Double layered braid work like this: the first braid layer takes the brunt of the pressure load and begins to go into tension. If the pressure is high enough, the braid wires begin to elastically deform until the second layer of braid can also go into tension and start helping with the pressure load. Thus, the load between the two braids is shared, but not in an even distribution.

It could be assumed that this additional braid layer would double the pressure rating, but the uneven distribution of pressure between braid layers results in an approximate pressure rating increase for a double braided assembly of about 1.6x over a single braided assembly.

As additional layers of braid are applied, there are diminishing returns for increases in pressure rating. An example of this is our 8 inch, 800 series hose:

- Single Braid: 234 PSI

- Double Braid: 450 PSI

- Triple Braid: 550 PSI

For this hose series and size, a double braided hose has a pressure rating 1.9x larger than a single braided hose, while adding third layer results in a 1.2x increase of the double braided pressure rating.

Relationship Between Braid and Hose Designs and Metal Hose Pressure Ratings

While braid is the primary pressure-carrying element of a metal hose assembly, it does not act in isolation. Design choices for the hose and end fittings play a role in the working pressures you see published in a hose manufacturer’s catalog.

In some burst testing scenarios, the hose may fail prior to the braid. For example, when testing our 700 Series double braided hose, the hose burst before the braid layers reached their yielding point. The hose failed while the braid remained intact. Pressure ratings were then based off a hose failure, not a braid failure. Increasing pressure ratings would require a heavier core capable of sustaining the loads that the braid can carry.

This is why simply adding heavier braid to a thinner-walled hose is not a practical approach to achieving higher pressure ratings: the hose core may fail before the braid is fully engaged.

An example of this braid and hose relationship is seen in comparing our 700 series hose with our 800 series hose:

| Hose Series | 700 Series | 800 Series |

| Nominal Size | 2” | 2” |

| Braid Construction | 48 x 9 x .020 | 48 x 9 x .025 |

| Hose Strip Thickness (in) | 0.15 | 0.20 |

| Single Braid MAWP (psi) | 516 | 810 |

To achieve a 2” hose rated for higher working pressures, we designed both a hose with a thicker strip and a braid with heavier diameter wire.

A Note on Maximum Allowable Working Pressure (MAWP)

Pressure ratings published in Penflex catalogs incorporate safety factors and reductions that reflect how the entire assembly behaves under load, not just the braid.

For most of our products, we use a 4:1 safety ratio to determine working pressures from burst pressures. For highly sensitive applications, like chlorine transfer, we use a 5:1 safety ratio.

Selecting braid with the appropriate construction and correct number of layers is essential, but not sufficient on its own. Achieving higher working pressures requires a balanced design where both the braid and the hose contribute to the assembly’s strength.

Understanding these relationships helps ensure the correct hose is selected for each application, maximizing safety and performance while avoiding over-engineering or incorrect assumptions about what “more braid” can accomplish when it comes to metal hose pressure ratings.