Specifying Hastelloy® C-276 for Corrosion Resistant Hose Assemblies

In aggressive chemical applications, a leaky hose isn’t just inconvenient—it is costly, hazardous, and often inevitable when the wrong alloy is used. While the 300 series stainless steels and even more corrosion resistant materials like Monel® 400 and Inconel® 625 offer excellent resistance against a broad range of service media, there are still applications where they fall short.

That’s where Hastelloy C-276 comes in.

In this bulletin, we’ll explore why Hastelloy is seen as the most corrosion resistant of common hose materials, where it is used, and what to consider when selecting it for flexible hoses.

Material Profile: What is Hastelloy C-276?

Developed by Haynes International in the 1960s, Hastelloy C-276 is a nickel-chromium alloy with high molybdenum content that’s primary characteristic is exceptional corrosion resistance. It is widely regarded as a “problem solver” alloy—specified when other materials have been deemed inadequate.

Do You Need a Hastelloy Hose for Your Application?

Are you working with sulfuric acid or hydrochloric acid? Phosphoric acid? Wet chlorine gas or chlorine solutions? Are your flex connectors failing prematurely?

Hastelloy C-276 is designed to resist general corrosion, stress corrosion cracking, pitting and crevice corrosion–as well as the intergranular corrosion that can affect the 300 series stainless steels during welding if proper procedure isn’t followed. As it can defend against many different kinds of corrosion, Hastelloy C-276 may be the best option in aggressive media applications.

Chemical processing, chlorine and sour gas transfer, and wastewater treatment are just a few examples of the industries that rely on Hastelloy C-276 flexible connections.

Hastelloy C-276 vs. Inconel 625

Both Hastelloy C-276 and Inconel 625 offer better corrosion resistance–in terms of breadth of compatibility as well as the rate at which material wear occurs–than the 300 series stainless steels. Both come with a higher price tag.

Hoses made from these alloys can be harder to source than hoses made from 304, 316L or 321 because not all hose manufacturers stock these superalloys. It requires an additional investment in inventory as well as training–not all welders with demonstrated track records of success with stainless steel hoses can fabricate assemblies made from these special alloys.

Hastelloy C-276 and Inconel 625 have a lot in common, so an engineer might wonder which one to use once it’s determined a stainless steel hose will not meet the application requirements.

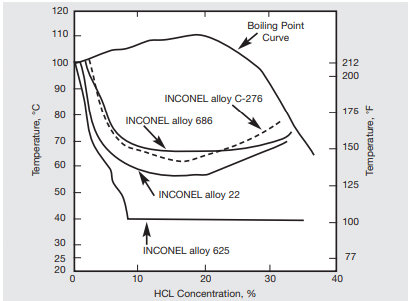

Generally speaking, the corrosion resistance of Hastelloy C-276 exceeds that of Inconel 625 in most service conditions. As an example, look at the iso-corrosion chart below sourced from Special Metals’ profile on Hastelloy C-276. (Special Metals refers to the material as Inconel alloy C-276 as they do not hold the trademarked “Hastelloy” name.) Hastelloy C-276 outperforms Inconel 625 across a wider range of concentrations and temperatures in hydrochloric acid service.

This is not always the case though. For instance, Inconel 625 is known to better resist the corrosive effects of nitric acid. Check in with one of our engineers if you’re unsure about the best option for your application.

An additional consideration is temperature. Hastelloy C-276 does not have the same high-temperature strength that Inconel 625 does. The practical service temperature limit for Hastelloy C-276 is 800°F. For Inconel 625, it is 1800°F.

Chlorine Transfer: Should You Use Hastelloy or Monel?

Safe drinking water and clean swimming pools come to mind when thinking about chlorine, but the list of use cases for this chemical is much longer. Chlorine is used to make various plastics and polymers–like PVC–solvents, pharmaceuticals, pesticides and advanced technologies like solar panels. It is a key ingredient in the manufacture of other chemicals like hydrogen chloride. It is used as a bleaching agent in pulp and paper applications. The list goes on–contributing to a wide range of products and services, chlorine plays a significant role in the US economy.

It is a toxic gas with corrosive properties–making safe transfer an area of focus for all players in the space. As a result, metal hoses are often used for chlorine transfer. Hastelloy C-276 is one of two metallic hose options allowed per The Chlorine Institute’s Pamphlet 6 Piping Systems for Dry Chlorine, Appendix A: Chlorine Transfer Hose. Monel 400 is the other.

While both materials are preferable to the non-metallic material options given permeability issues, Hastelloy is considered to be the best option for chlorine transfer given it resists chlorine corrosion better than Monel.

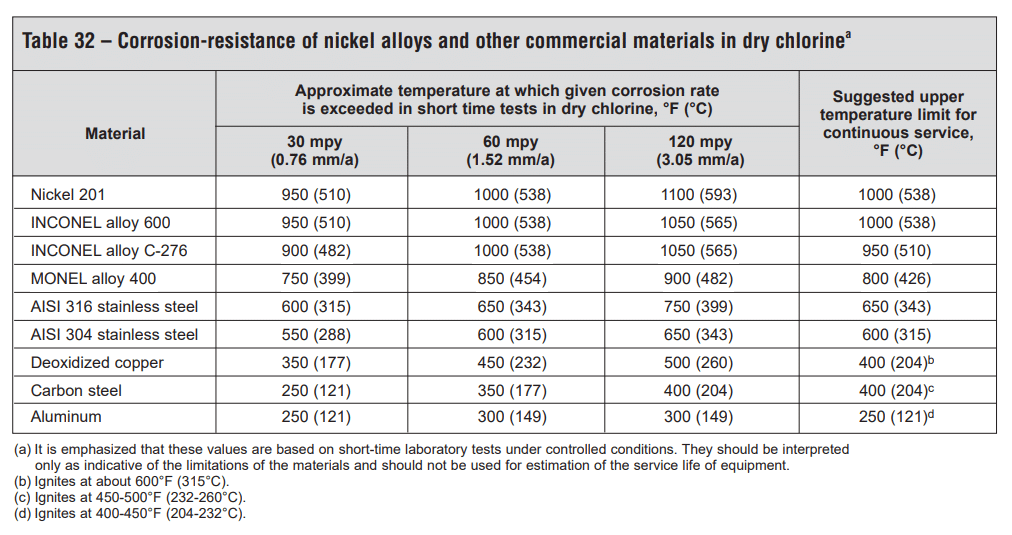

The table below, sourced from Special Metals’ High-Performance Alloys for Resistance to Aqueous Corrosion, shows Hastelloy C-276 resists material wear from dry chlorine to a greater degree as temperatures climb. While these temperatures far exceed what’s typically seen in chlorine service, the information serves as a general ranking of alloys in one kind of chlorine service.

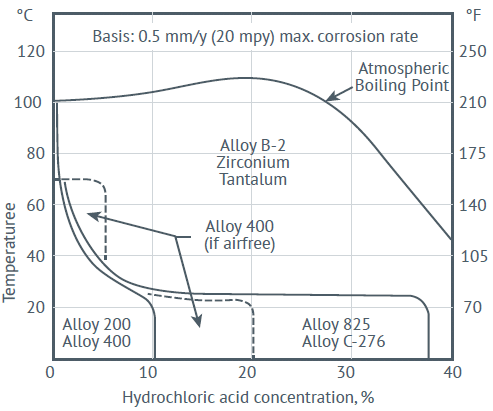

Hastelloy C-276 is better suited to handle hydrochloric acid than Monel 400 as well. This extremely aggressive media forms when chlorine dissolves in water. While all measures are taken to avoid the ingress of moisture into a chlorine piping system, sometimes it happens–and if it does, a Hastelloy hose will provide an additional measure of safety.

Making Hastelloy C-276 Hoses: Consider Welder Skill and Experience

Welding sheet metal demands great skill. The level of precision required is immense–for instance, consider ¼” P3. The material is a mere .006” thick!

All Penflex welders are certified to the industry’s highest standard ASME Section IX, but to weld special metals like Hastelloy C-276, Inconel 625 and Monel 400, they must have at least one year of experience welding stainless steel hoses.

While the processes and techniques are the same whether welding Hastelloy-to-Hastelloy or stainless-to-stainless, there is less room for error. The special alloys are unforgiving and, as a result, weld discontinuities and leaks are more common. Welders must consistently deliver to a greater degree of precision and the ability to do so often comes down to more than training: experience.

Hastelloy C-276 Hose Assemblies from Penflex

Penflex is one of the few US hose manufactures to stock Hastelloy C-276 (UNS N10276) hose and braid, in sizes ½” – 8”, and employ welders trained and experienced in making assemblies from this exacting material.

When other hose materials won’t cut it, Hastelloy C-276 offers longer service life in many corrosive applications. If you are dealing with especially aggressive media, or are seeing corrosion-related premature failures with your current hoses, reach out to talk to an engineer about your application.