Monel® 400: Serving Marine and Chemical Processing Industries for Over a Century

When corrosion is a concern, material selection becomes one of the most important design inputs in any piping system. Choosing the wrong alloy can shorten service life, lead to equipment damage and—if hazardous media is involved—create safety risk.

While stainless steels like 316L and 321 perform well in many environments, some applications call for more specialized materials. In systems where chlorides are present—like seawater or certain chemical processing applications—Monel 400 may be the better choice.

What is Monel alloy 400?

Monel 400 is a nickel-copper alloy developed by the International Nickel Company (INCO) in the early 1900s to combat steel corrosion. The inclusion of nickel–which comprises at least 63% of Monel alloy 400 composition–encourages the formation of a protective layer at the material surface. This layer acts as a protective barrier, preventing corrosive elements from reaching the underlying metal.

In addition to imparting corrosion resistance, nickel, along with manganese and silicon, improve the strength and toughness of Monel 400. The combination of these characteristics made Monel a popular choice in marine applications. The grey-green patina it develops over time led to the metal’s use in architectural elements as well, the roof of New York City’s original Pennsylvania Station being just one example!

Once stainless steel was developed, the higher costs associated with Monel meant use was limited to those applications where the then more readily available 300 series alloys fell short.

What is Monel alloy 400?

Monel alloy 400 is still widely used for flexible connections in marine piping systems. Typically, service media is flowing seawater. In stagnant seawater applications, susceptibility to pitting and crevice corrosion might steer a piping engineer to another nickel alloy like Inconel® 625.

It is generally recommended to use Monel braid and end fittings when designing a Monel hose assembly. This is especially true if the hose is submerged in seawater. Corrosion can work its way from the outside to the inside of a hose as easily as it can from the inside out in certain conditions.

Chemical Processing and Monel 400

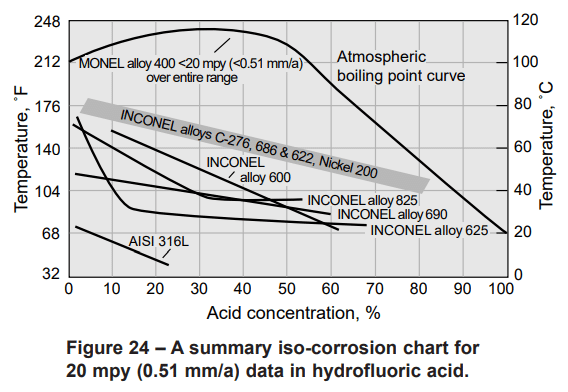

Monel 400 flex connectors and transfer lines are common in chemical processing applications as well. Beyond the corrosion resistance offered in various chloride applications, the alloy also exhibits great resistance to hydrofluoric acid in all concentrations up to the boiling point and to many forms of sulfuric and hydrochloric acids under reducing conditions.

The iso-corrosion chart below from Special Metals’ High-Performance Alloys for Resistance to Aqueous Corrosion shows Monel to be the best option for hydrofluoric acid service.

Chlorine Transfer: Should You Use Monel or Hastelloy®?

One notable chemical application is chlorine transfer. Monel is one of two metallic hose options allowed per The Chlorine Institute’s Pamphlet 6 Piping Systems for Dry Chlorine, Appendix A: Chlorine Transfer Hose. Hastelloy C-276 is the other.

While Monel is preferable to the non-metallic hose options given permeability issues, Hastelloy C-276 does exhibit superior resistance to chlorine corrosion. It is, however, the more expensive option. When cost is a limiting factor, Monel is an accepted alternative for chlorine transfer hoses.

Material Compatibility: Penflex Corrosion Resistance Chart

Many strip suppliers and hose manufacturers provide charts comparing the various levels of corrosion resistance among alloys with specific flow media. Penflex’s chart offers an easy way to compare the corrosion resistance of Monel 400 to that of the 300 series stainless steels that are more commonly used in process and transfer piping systems.

Making Monel 400 Hoses: Consider Welder Skill and Experience

Welding sheet metal demands great skill. The level of precision required is immense–for instance, consider ¼” P3. The material is a mere .006” thick!

All Penflex welders are certified to the industry’s highest standard ASME Section IX, but to weld special metals like Monel 400, Inconel 625 and Hastelloy C-276, they must have at least one year of experience welding stainless steel hoses.

While the processes and techniques are the same whether welding Monel-to-Monel or stainless-to-stainless, there is less room for error. The special alloys are unforgiving and, as a result, weld discontinuities and leaks are more common. Welders must consistently deliver to a greater degree of precision and the ability to do so often comes down to more than training: experience.

Monel 400 Hoses from Penflex

Penflex is one of the few US hose manufactures to stock Monel 400 (UNS N04400) hose and braid, in sizes ¼” – 3”, and employ welders trained and experienced in making assemblies with this exacting material.

When the 300 series stainless steels won’t cut it, Monel 400 offers longer service life in many marine and chemical processing applications. If you’re dealing with hoses in a harsh environment, reach out to talk to a Penflex engineer about your application.