Purge Tools

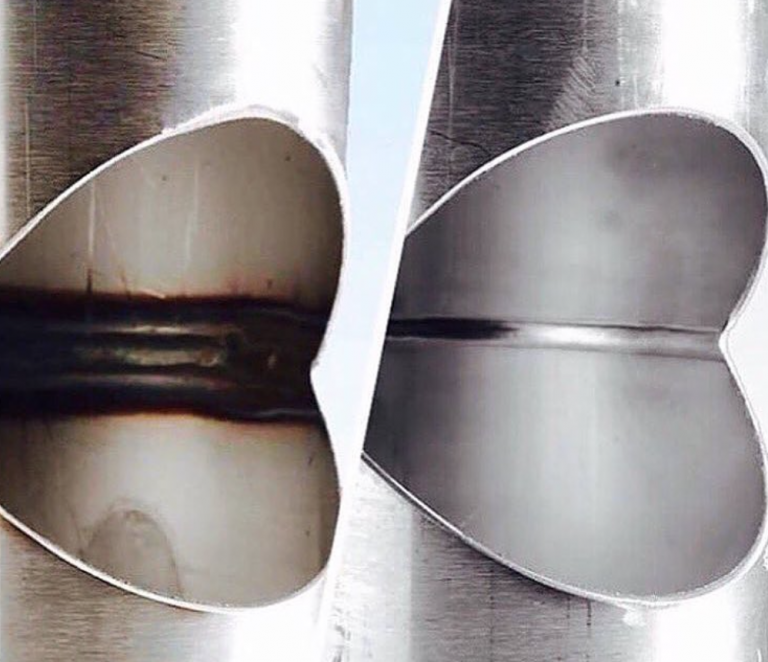

Purging is a proven process for enhancing the quality of welds. It ensures weld quality by decreasing—or even preventing—oxidation which in turn increases corrosion resistance. Given resistance to corrosion is one of the primary reasons users opt for stainless steel, maintaining this characteristic throughout the manufacturing process is essential.

Additionally, as welders can better control the melt when purging, there will be a smaller heat affected zone (HAZ) around the weld. The HAZ is a target for chemical attack, so minimizing this area will also help to ensure longer hose life.

Sugaring (hose on left) is the telltale sign of an unpurged weld. Purged welds (hose on right) do not show signs of burn through, and instead present a fully penetrated and consistent arc.

Penflex Purge Tools

Penflex manufactures a line of purge tools for hose sizes ¼” to 12” to assist with back purging welds. The tools are designed and engineered to fit Penflex’s most common hose sizes based on their respective tolerances, and for use in our welding turntables.

| Size | Part Number | For Use With Penflex Series |

|---|---|---|

| ¼” | PURGE004 | P3/P4 |

| ¼” | PURGE005 | 700/800/900 |

| 5/16” – P3 | PURGE005-P3 | P3 |

| 5/16” – P4 | PURGE005 | P4 |

| ⅜” | PURGE-006 | P3/P4/700/800/900 |

| ½” – P3 | PURGE008-P3 | P3 |

| ½” | PURGE008 | P4/700/800/900 |

| ⅝” | PURGE010 | P3 |

| ¾” | PURGE012 | P3/P4/700/800/900 |

| 1” | PURGE016 | P3/P4/700/800/900 |

| 1-¼” | PURGE020 | P3/P4/700/800/900 |

| 1-½” – P3 | PURGE020-P3 | P3 |

| 1-½” | PURGE024 | P4/700/800/900 |

| 2” | PURGE032 | P3/P4/700/800/900 |

| 2-½” | PURGE040 | P4/700/800 |

| 3” | PURGE048 | P4/700/800 |

| 4” | PURGE064 | P4/700/800 |

| 5” | PURGE080 | 700 |

| 6” | PURGE096 | 700/800 |

| 8” | PURGE128 | 700/800 |

| 10” | PURGE160 | 700 |

| 12” | PURGE196 | 700 |