Engineering Bulletin #150

One of the primary reasons we use metal hose is because it is corrosion resistant. In aggressive applications, other hoses—rubber or PTFE for example—simply cannot handle the media without deteriorating.

Many end users focus on alloy selection when it comes to fighting corrosion. This makes sense as even among the available alloy grades resistance to media varies. The flexible metal hose industry relies on 321 and 316L for the bulk of its needs, but there are many alloys that offer superior resistance to corrosion.

For instance, The Chlorine Institute recommends Monel® 400 and Hastelloy® C-276 for metallic hoses used in chlorine transfer for their increased compatibility with chlorine. Even within the chlorine industry, Hastelloy® C-276 is generally considered a better option than Monel® 400.

The need to select the right alloy for your application is an important one, but it is not the only one. The wall thickness of the hose is a critical feature to be aware of. Media inside and sometimes in the environment outside the hose will, at some level, penetrate the hose. It may be that the penetration is only to an insignificant degree, or it could be that is enough to impair the integrity of the hose.

Where corrosion is present, a thicker wall hose will provide a longer life than a thinner wall hose made of the same alloy and used in the same application.

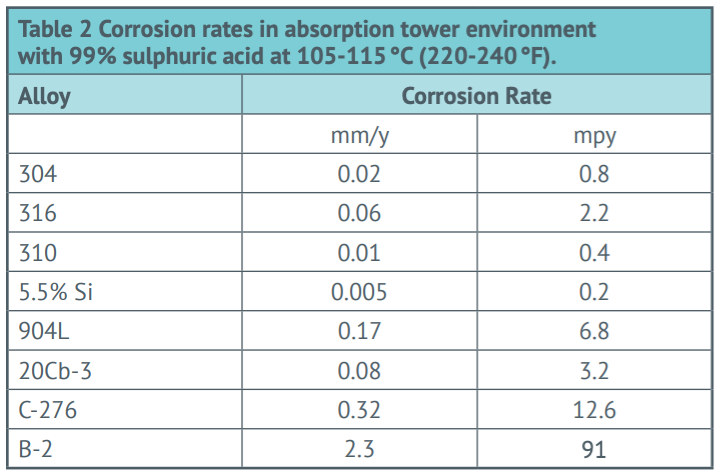

Expected Rates of Corrosion

Corrosion rates, or the speeds at which metal deteriorate, help illustrate the role wall thickness plays in determining corrosion resistance.

Millimeters per year (mm/y) and Mils penetration per year (MPY)—a unit of measurement equal to one thousandth of an inch—are used to measure these rates.

For instance, 316 SS is compatible with sulfuric acid. At 99% concentration, sulfuric acid moving through a 316 hose has a 2.2 MPY expected rate of corrosion. This may not be an issue with a Schedule 40 pipe, but on a 0.010” wall hose, that’s 20% of the wall thickness. That is an issue!

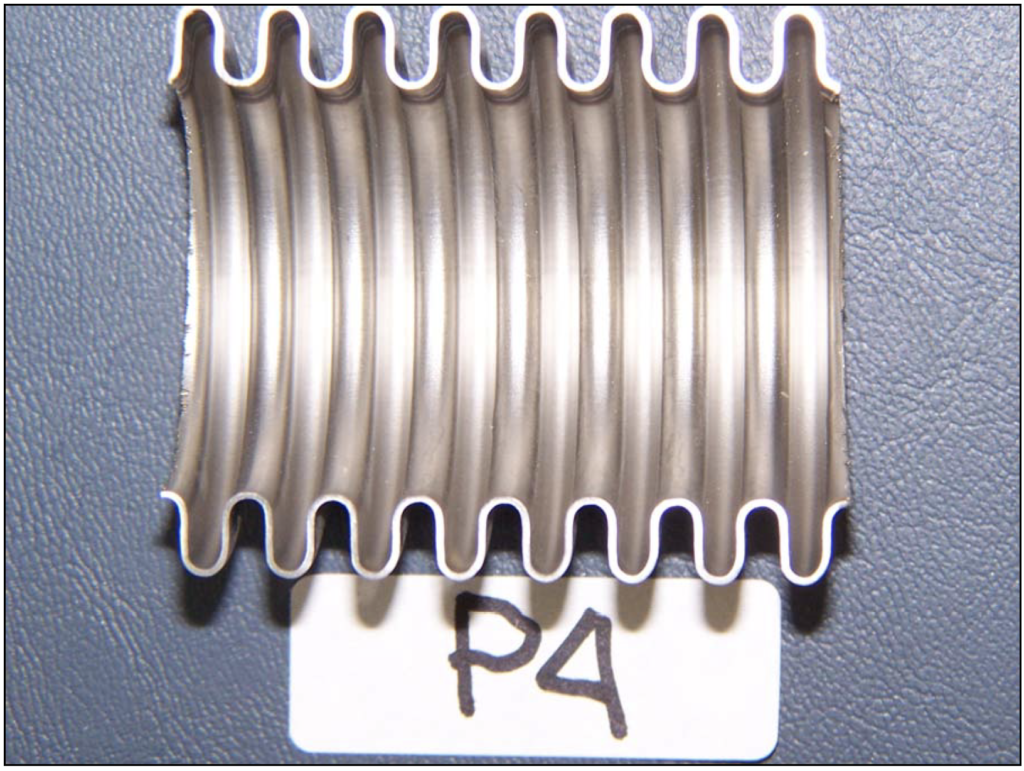

Penflex Heavier Wall Hoses

Penflex leads the industry in wall thicknesses. For our 1” P4, the wall thickness is 0.015” but other manufacturers offer 1” hoses with wall thicknesses of 0.010.” In the above situation, a Penflex P4 hose would be in service for more than 2 years before approaching the wall thickness of a new hose made with 0.010” material. That’s worth thinking about!

Wall thickness matters. If you don’t consider that, then you could be using a thinner hose in a potentially dangerous scenario.