Engineering Bulletin #167

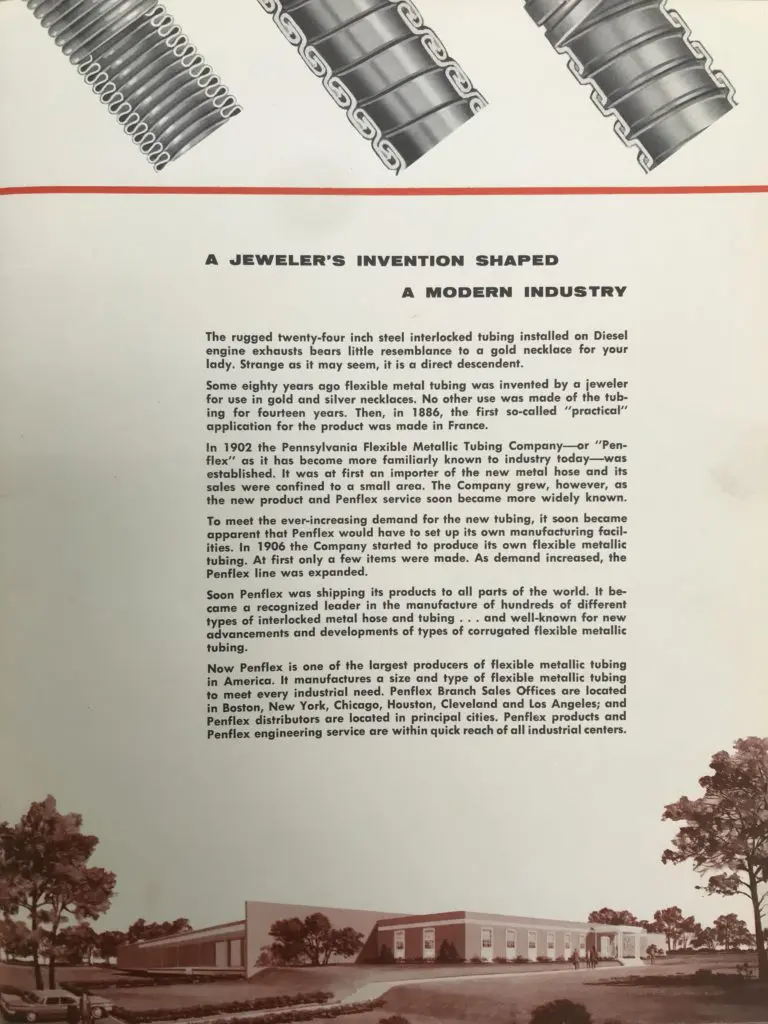

“The rugged twenty-four inch steel interlocked tubing installed on diesel engine exhaust bears little resemblance to a gold necklace for your lady. Strange as it may seem, it is a direct descendent.”

Excerpt from Penflex’s 1959 Flexible Metal Hose catalog

When the inventors of interlocked hose first thought to fold the edges of thin metal strip together in a spiral-like fashion, thereby creating a flexible sheath, it wasn’t a means of fluid conveyance they sought.

Jeweler’s Invention Shapes A Modern Industry

It was the mid-1800s and Heinrich Witzenmann and Louis Kuppenheim wanted to create something elegant, and purely ornamental. And the competition was stiff.

Pforzheim, on the outskirts of the Black Forest in southwest Germany, had been dubbed “Goldstadt,” or “Gold City,” given the proliferation of jewelers and watchmakers that had come to call it home. If the pair’s creation was to stand out, it needed to be truly unique.

And their necklace was, though in a way the two had probably never envisioned. It was more than ten years after developing the design that the jewelers recognized its potential in industrial applications. A new branch of their business dedicated to the development and production of interlocked hose was subsequently opened.

A Geometric Design

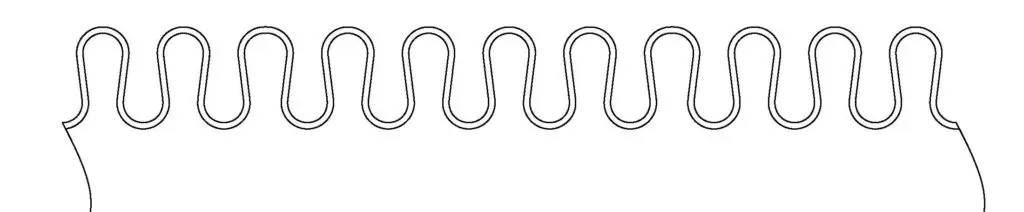

To create interlocked hose, the edges of strip material are folded into one another. As the material runs into the machine, one edge is bent up and inward to create a curl running the length of the strip. As it continues its path, winding helically around a sizing mandrel, the other edge is folded into the curl.

This creates the interlocked convolutions that enable the hose to move. Movement is determined by the amount of space between the two folds and, as seen in the cross section above, this space creates an exit path for media. Interlocked hoses are not leak tight and, as a result, cannot be used in applications with pressure requirements.

Inclusion of Packing Materials

In an attempt to deliver some pressure carrying capacity, manufacturers began to add packing material into the interlocked convolutions. However, gains were measured. For instance, Penflex’s interlocked hose–regardless of size–when packed with silicone is rated to just 20 PSI.

These days, when used alone, interlocked hoses convey small solid particles like grain or plastic pellets for injection molding machines. The packing is not tight enough to seal against leaks from a liquid.

Further gains came with the introduction of Penflex’s M-100 Pressure Hose, an interlocked hose with a specially formed groove to accommodate the packing material. Two-inch M-100 hose is rated to 190 PSI.

While the packing does serve as a continuous gasket to make the hose pressure tight, we would limit its use to air and non-searching fluids at moderate pressures and temperatures.

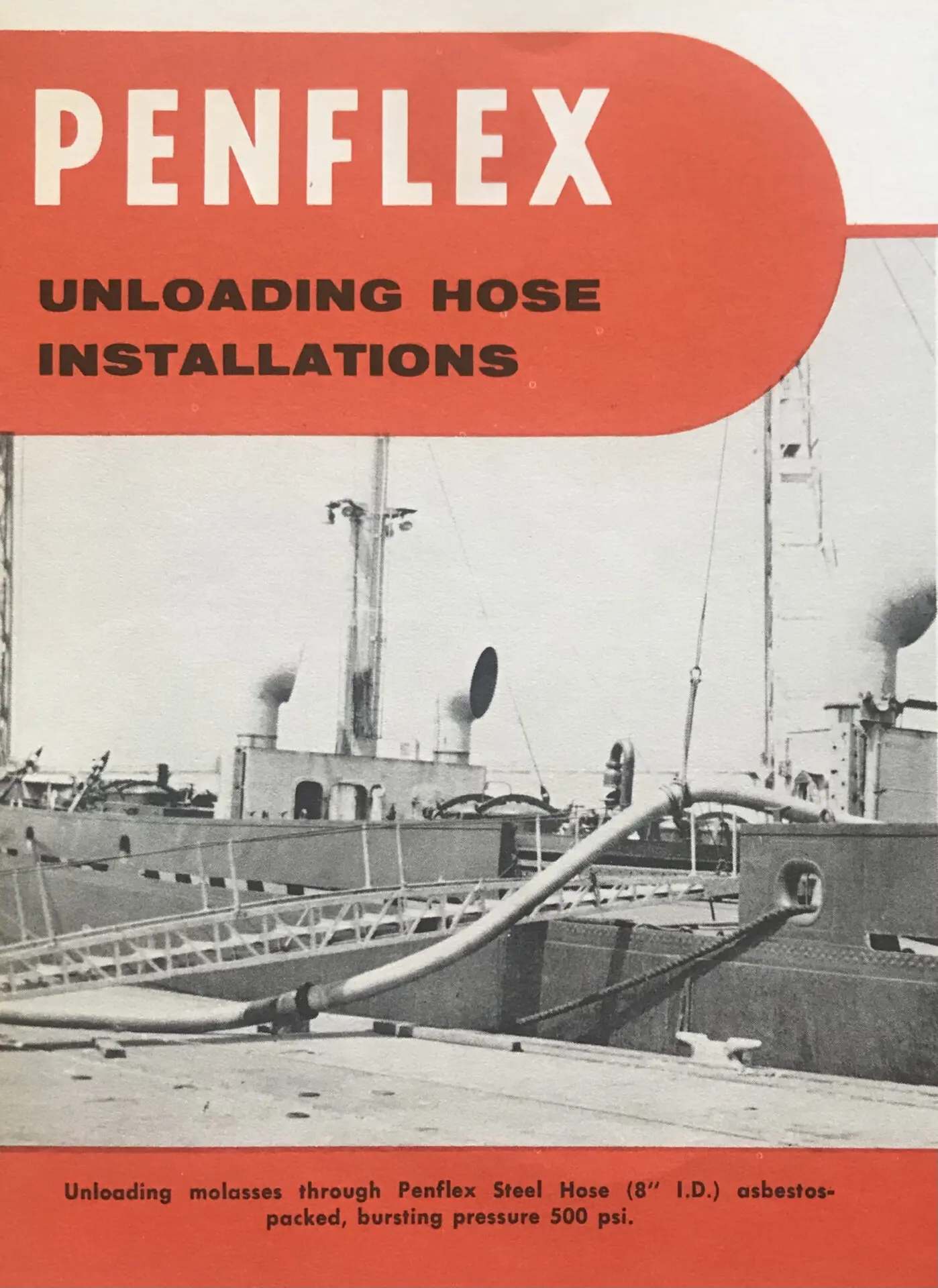

Historically, suggested applications for M-100 included steam hoses, cleaning boiler tubes, tar and asphalt hoses, vegetable oil hoses, diesel exhaust, expansion joints, rivet passing and conveying molasses. The hose’s heavy wall construction enables it to withstand significant external pressure, and M-100 has been used successfully in underground and underwater applications as well.

With either design, temperature is a consideration given the packing material cannot withstand the same high temperatures that metal can. This may not be a concern given operating conditions but consider the heat of welding. Materials adjacent to the end fitting weld experience temperatures in excess of 800°F. The packing can “burn out” and leave a leak path in its wake.

The limitations on pressure and temperature left room for further innovation.

Advent of Corrugated Hose Technology

Judging by records from the US Patent and Trademark Office, corrugated hoses were making their way to market by the 1930s and 1940s. Initially the hoses were created in a similar way to their interlocked predecessors. The main difference was that rather than folding the edges together, they were crest welded.

A pressure tight seal had been achieved!

Soon a more efficient method was developed whereby the strip was welded into a tube before being run through a corrugator to create the corrugations. Today’s corrugated hoses are made this way–though some machines now combine tube making and corrugation creation in a single, continuous process.

Most feature an annular hose profile, and can achieve pressure ratings far in excess of their interlocked counterparts. Penflex’s 2-inch P4 hose with one braid layer is rated to 532 PSI. With two braid layers, it is rated to 850 PSI.

While interlocked hoses are still used, both alone and as accessories on corrugated hose assemblies, the fact that they are not 100% leak proof is one of the main reasons they have largely been displaced by corrugated hoses.