How to Avoid the Most Common Mistake When Welding a Cap Pass

The braid on a metal hose must be kept in tension if it is to play its role as pressure carrier well. Without it, under pressure, a hose will grow back into a tube.

Compress a hose axially, and the braid will fall out of tension. Therefore, we do not use braided hoses to absorb axial movement. (A hose can absorb axial movement in a piping system if it is hung in a loop. In this configuration, the hose does not move axially though.) Fail to capture all braid wires in a cap pass, and those wires left out are no longer, or rather, never were, in tension.

Pressure ratings depend on all braid wires remaining in tension during operation. Theoretically, every wire carries an equal portion of the pressure and a few loose wires can reduce a braid’s pressure capacity below the intended working pressure.

The Cap Weld

Cap pass welds connect a hose and braid. They precede any fitting attachment welds and are judged based on several criteria, whether all braid wires are captured chief among them.

Beyond a reduction in pressure ratings, once wires pull out from the cap pass, the area of the hose just behind it becomes more susceptible. If any cycling or bending is taking place, fatigue will set in sooner, resulting in premature cracks and, eventually, failure.

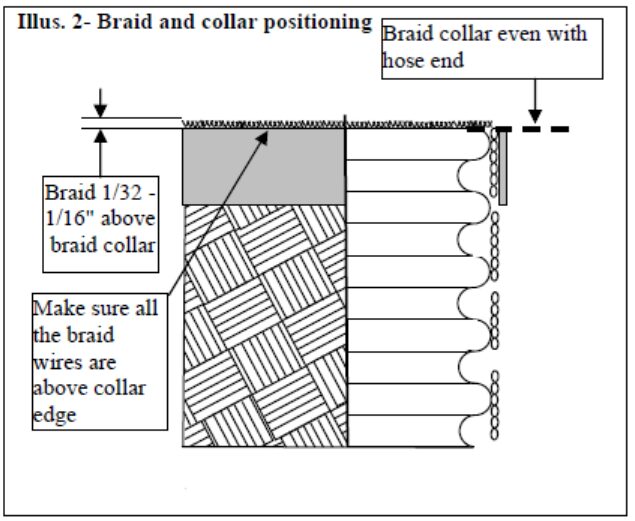

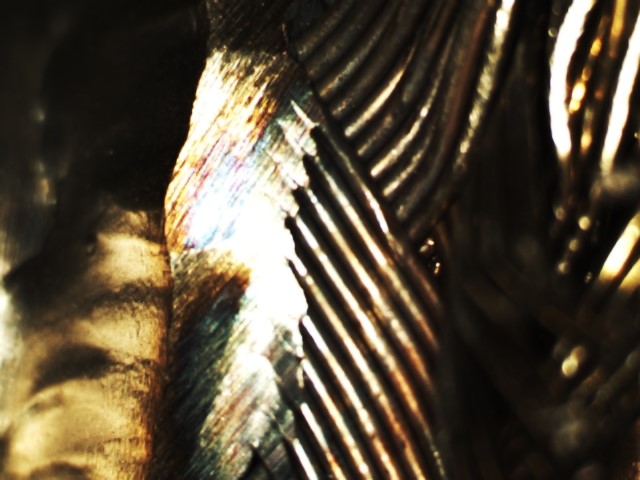

The image below offers an example of braid wires that were not captured in the cap pass. In this instance, given the number of wires and their uniform geometry, it is likely significant sections of the braid slipped below the top of the ferrule during the welding process, never even coming into contact with the puddle spanning hose to ferrule.

If only a few wires were missed, localized stress at the end fitting caused by mechanical bending, vibration or other application forces could have contributed to pulled out wires.

Approaches to Welding the Cap Pass

Aside from skilled welding technique, the best way to ensure all braid wires are captured is to pull the braid 1/16” above the ferrule before welding.

Keeping the braid flush with the hose may make for easier welding, but the likelihood of failing to capture all braid wires offsets any potential gains in time saved by taking this approach.

Capturing every braid wire is not the only consideration for a good cap weld. A common approach, known as the burn down method, accomplishes this goal but fails to take into account two important details.

First, this weld cannot be purged and therefore ignores the metallurgical effects of welding. (For more information about argon purging, and its role in delivering high quality welds, have a look at this bulletin).

Second, the uneven geometry reduces the attachment weld flexibility and special care must be taken to ensure proper joint fit-up. This is important to ensure joint strength and quality.

Penflex’s method eliminates these issues and accomplishes the goal of capturing the braid wires while allowing for purging and creating an easy geometry for the attachment weld.

The Cap Pass Gold Standard

Here’s a look at a well-executed cap pass. In the first image, the ferrule has been removed, and looking at the braid from the outside, we can see there are no loose wires. In the second image, a close trim cross-section of the wire in the cap pass shows that 100% of the wires were captured.

Penflex Welder Training

Cap passes of this caliber are consistently achievable, with proper training. Penflex offers a one-week ASME Section IX-certified program for welders with mid-level experience. The training is designed to improve technique, and perfecting cap pass welds is one of the skills achieved through the training.

For more information about our Welder Training Program, please click here.

Online Welder Training Course

For welders planning to attend Penflex’s Welder Program, or for those who have already completed it and are looking for a refresher, we offer an online welder training course. In the span of 30 minutes, our Certified Welding Educator reviews materials, join configurations, assembly prep and technique for cap and end fitting attachment welds.

To check out our course library, click here.

To print this bulletin, please click here.