Products

From our lightweight, flexible P3 Series to the triple-braided heavy-duty 1400 Series, Penflex can accommodate applications from the least to most demanding. Using different alloys, wall thicknesses, hose diameters, pitches and corrugation counts allows us to meet various temperature, pressure, movement, and corrosion resistance requirements.

What Hose Sizes and Alloys Are Available

Metal hoses range in size from ¼”- 24” and are available in 321 or 316L stainless steel with single or double layers of 304L or 316L braid. 700 Series is the exception with options for Monel™ 400, Hastelloy™ C276, Inconel™ 600, Inconel™ 625, Incoloy™ 825, AL-6XN™, and Bronze. These high nickel alloys offer increased corrosion resistance while bronze is often called for in HVAC applications. Other alloys are available upon request.

Penflex also understands that unique applications require unique products and is committed to manufacturing products that customers need. Penflex has the technology and know-how to create custom hose products that meet specific application requirements.

Contact Us with Your Specific Hose Needs

P3 vs. P4 Series Stainless Steel Hoses

The P3 and P4 Series Stainless Steel Hoses are two of our most popular hose products and a comparison between them hints at our range of offerings. Both Series are manufactured and tested in accordance with ISO 10380 International Standards.

Sales engineer Ronit Patil discusses the distinctions revolving around wall thickness, hose geometry and sizes available.

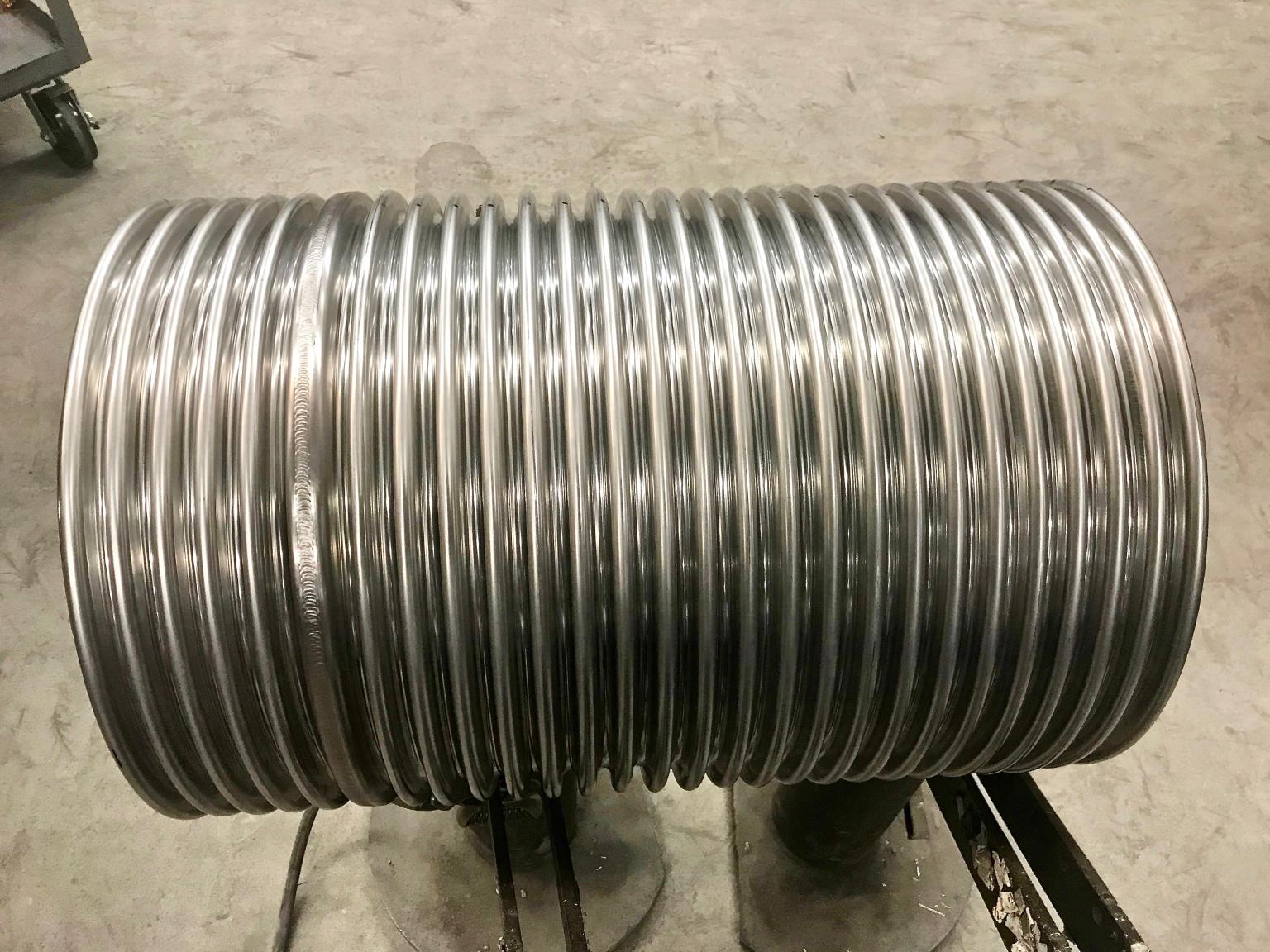

700 Series Hose and Braid

Penflex 700 Series corrugated hose is a high-quality general purpose industrial hose. Our manufacturing process produces long lengths, which are packaged in standard cartons or as braided hose-on-reels.

Furthermore, Penflex single and double braided 700 Series sizes 2 ½” to 12” (DN65 – DN300) comply with DNV GL standards pertaining to metal hose.

What to Use in High Pressure Applications

Penflex 800, 900 and 1400 Series heavy duty hoses feature a robust heavy wall construction for high-pressure applications and increased resistance to chemical corrosion. The 1400 Series stainless steel hose is designed for the most extreme pressure applications. Its three or four layers of heavy-duty braid is constructed to sustain the highest working pressures and provide maximum protection to the inner core.

How About in Corrosive Applications

Corrosion resistance is one of the primary reasons we use metal hose. In aggressive applications, other hoses—rubber or PTFE for example—simply cannot handle the media without deteriorating.

Made using the austenitic 300 Series stainless steels, many of Penflex hoses are designed with a heavier wall construction to ensure longer resistance to chemical corrosion. Given expected rates of corrosion, these heavier wall hoses outlast thinner wall price competitive hoses, ultimately saving time and money in replacement costs and down time.

The flexible metal hose industry relies on 321 and 316L for the bulk of its needs, but there are many alloys that offer superior resistance to corrosion. For instance, The Chlorine Institute recommends Monel® 400 and Hastelloy™ C-276 for metallic hoses used in chlorine transfer for their increased compatibility with chlorine. Even within the chlorine industry, Hastelloy™ C-276 is generally considered a better option than Monel™ 400. Penflex offers other high-nickel alloys like Inconel™ 600, Inconel™ 625, Incoloy™ 825 and AL-6XN™ as well.

P5 Series Large Bore Hose and Braid

Penflex P5 Series large diameter hose and braid is the latest addition to our extensive product line, delivering the same high-quality corrosion resistance customers have come to expect from our other industrial hoses in larger sizes than ever before.

With inside diameters (I.D.) spanning 14” – 24”, P5 Series is typically used in low pressure applications where absorbing vibration is a primary concern.