Expansion Joints in Steel Mills

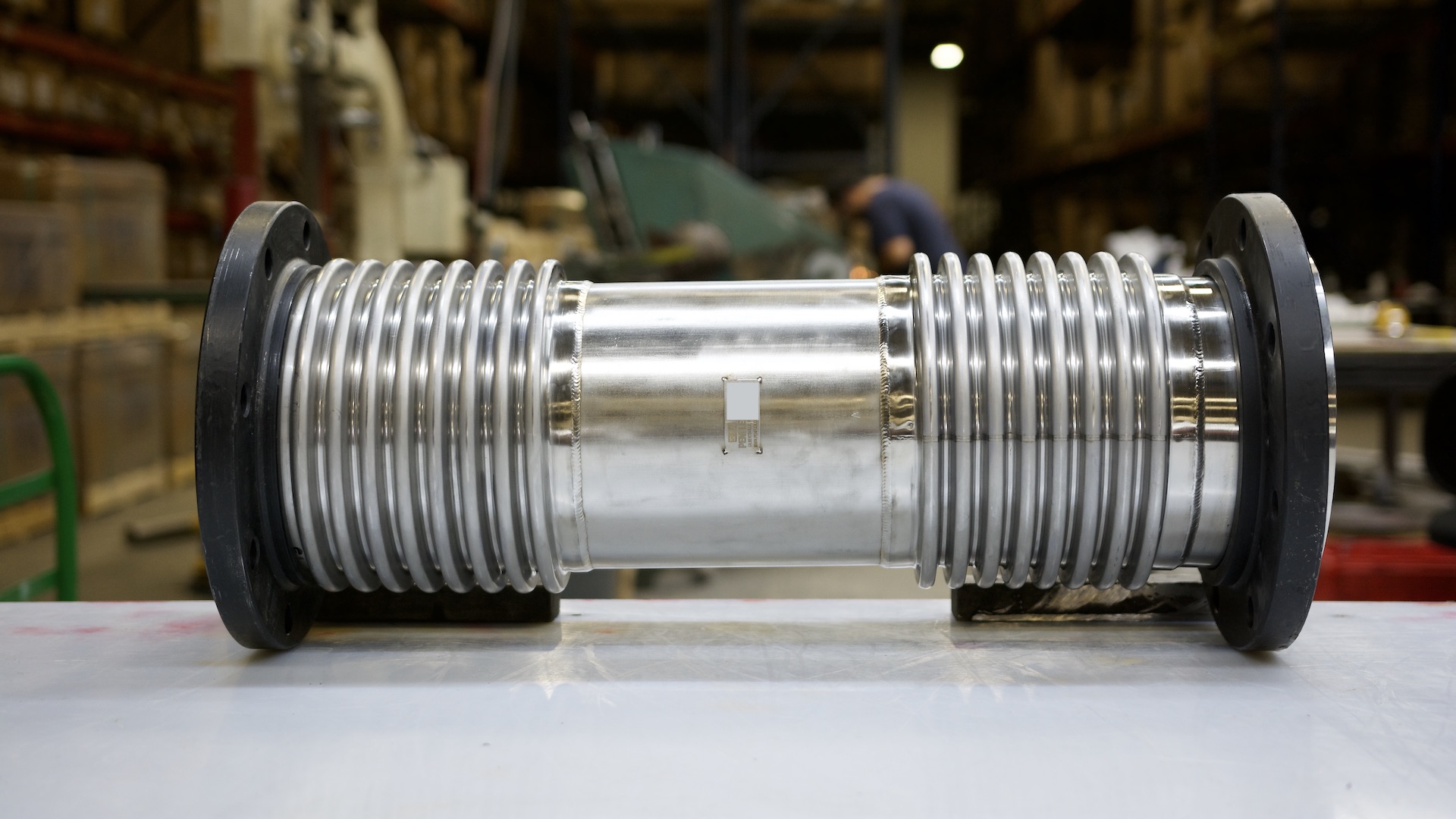

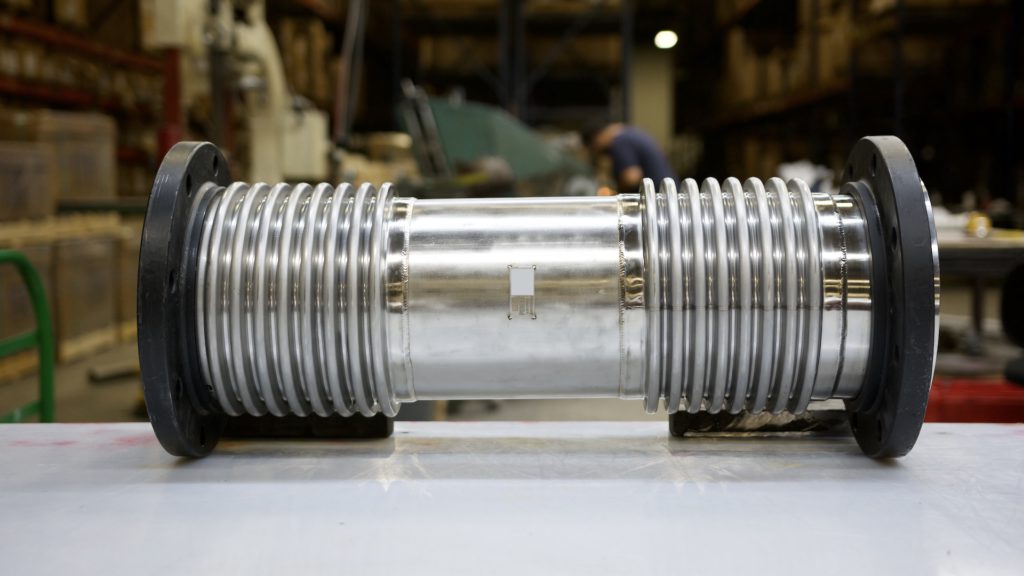

Expansion joints in steel mills accommodate movement and absorb vibration in piping systems. In doing so, they protect adjacent piping and equipment from damage.

Penflex designs and manufactures a wide range of metal bellows and expansion joints for steel mills that play in important role in the functioning of key equipment such as blast furnaces.

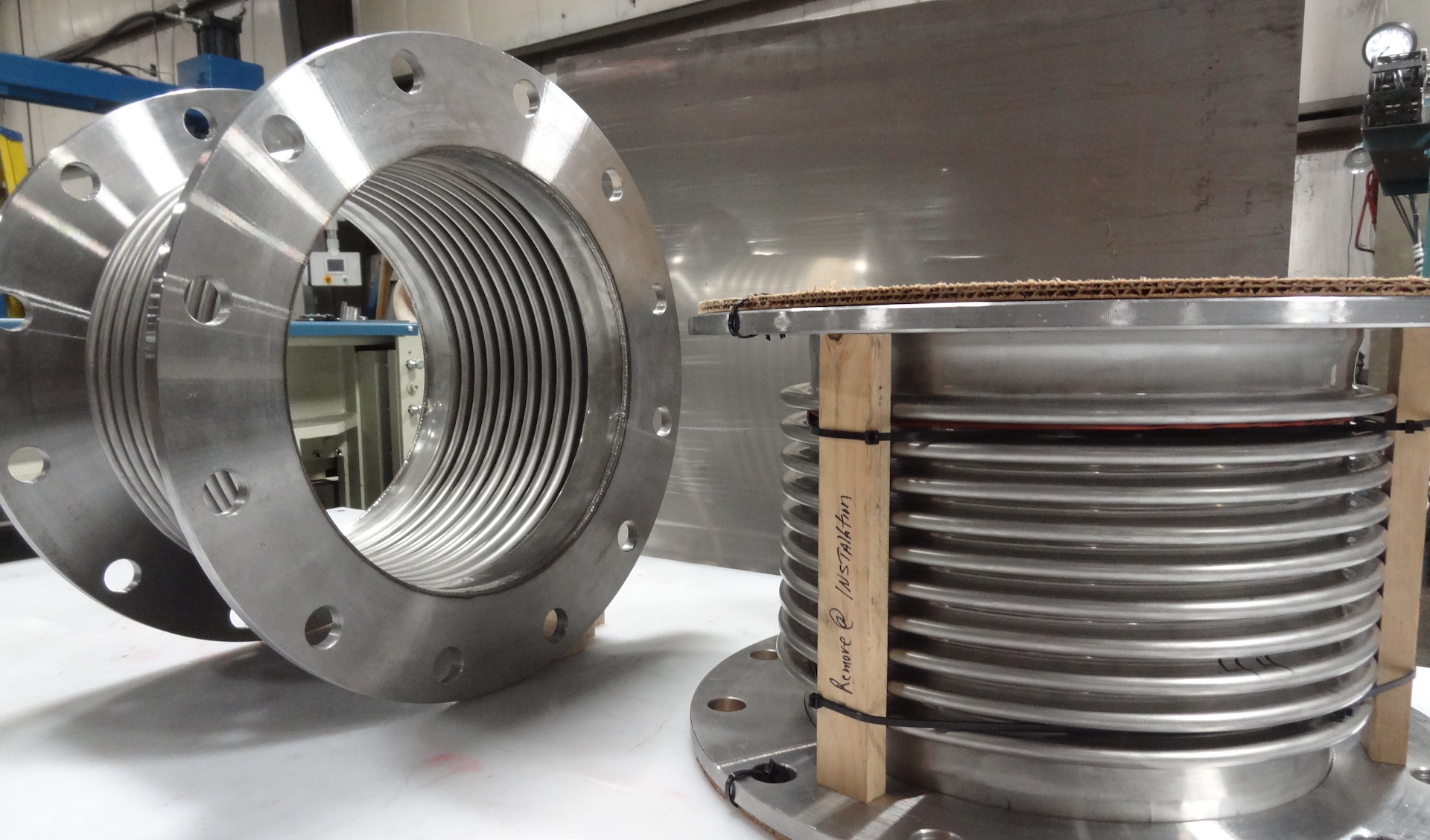

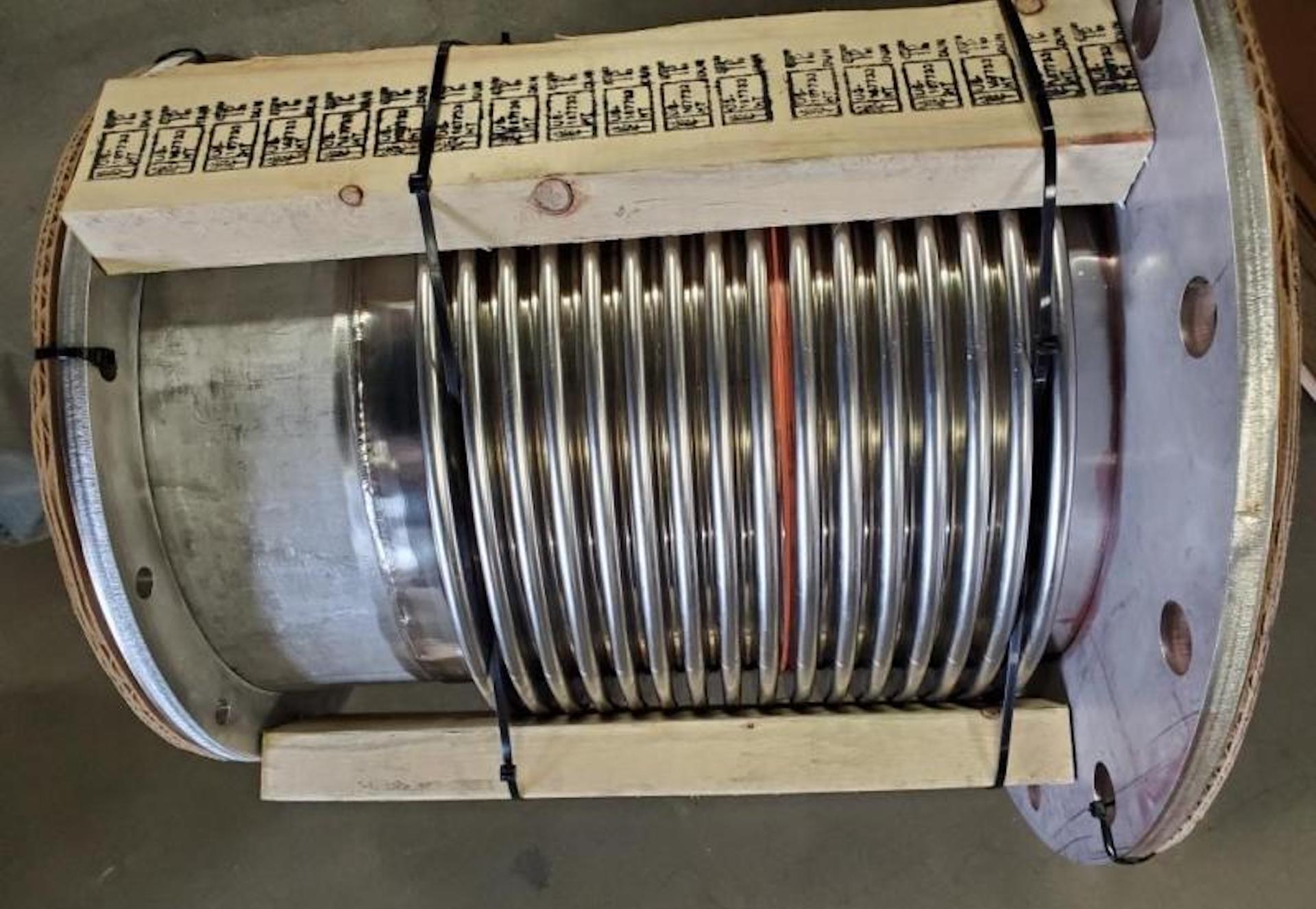

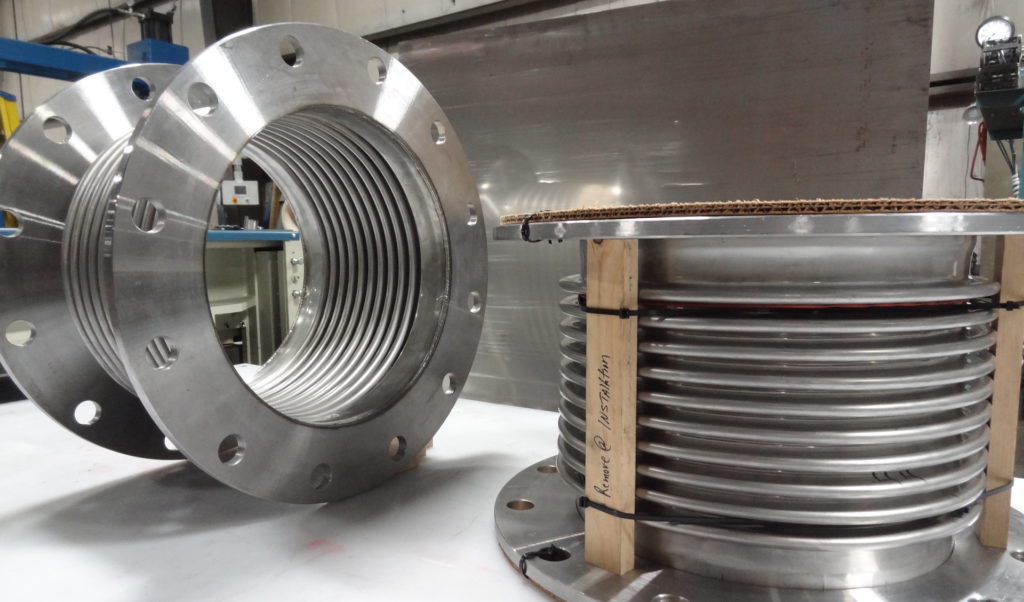

Heat is often the main concern in steel mill applications. However, corrosion can also be a cause for concern in certain applications, such as those involving coke oven or furnace gases. Certain alloys, like 800H, Nickel 200, Titanium Grades 1 and 2 and Duplex 2205, can be used in extremely hot or highly corrosive applications.

Penflex Expansion Joints

Blast System Furnace

Blast furnaces use chemical reactions between hot air and an iron ore-coke-limestone mix to produce molten slag and molten iron. The molten mix heats further with additional inputs to make steel.

Expansion joints are used within piping in and out of the furnaces to help accommodate thermal expansion and contraction. Depending on proximity to the furnace, and ambient temperatures, the components may be made using a higher-nickel alloy, like Inconel 625, which is better suited for extreme temperature environments.

Coke Gas Lines & Coke Oven

Coke ovens are similar in structure and technology to blast furnaces, used to turn coal into a more efficient energy source: coke. Aside from coke, coke oven gas is a byproduct of the process. It can contain chemicals like ammonia, tar, sulfur, naphthalene, benzol, and most notably carbon monoxide, meaning parts designed for coke applications will likely need to keep corrosion resistance in mind.

Combustion Lines

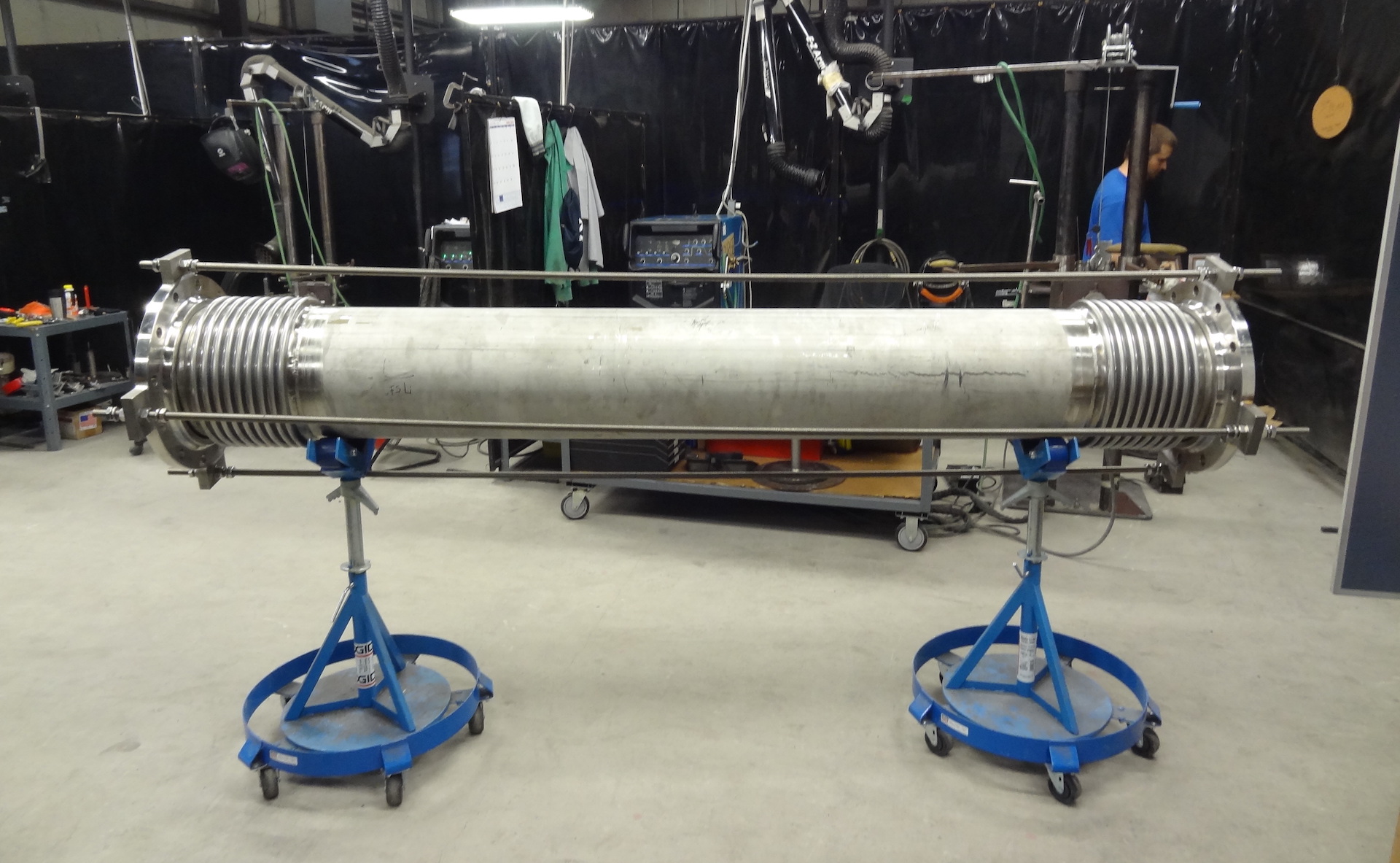

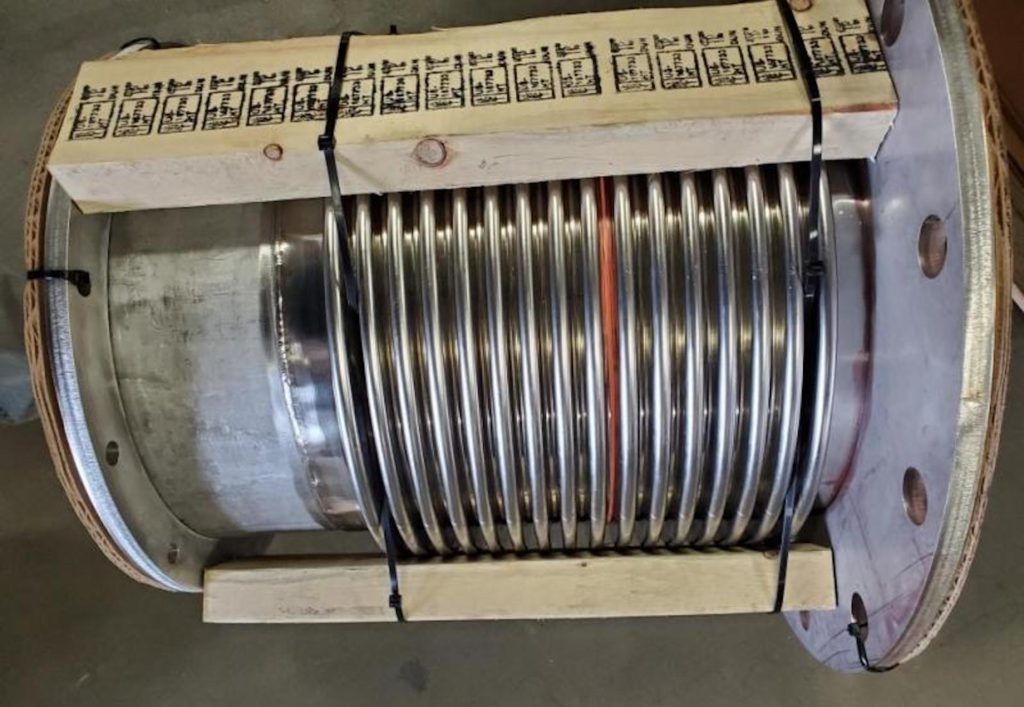

Combustible gases produced from coke ovens, blast furnaces, and basic oxygen furnaces are repurposed at different stages of the steelmaking process and expansion joints are often used to help accommodate movements in the piping system as these byproducts are moved within the mill.

Gas Cleaning System

Gas cleaning systems in steel mills clean exhaust gases, reducing air pollution. To compensate for vibrations and movements caused by thermal expansion and contraction, expansion joints are often required. This protects surrounding piping and equipment from damage.

Similar to gas cleaning systems, the baghouse controls emissions from the blast furnace.

Water Cooler Ducts

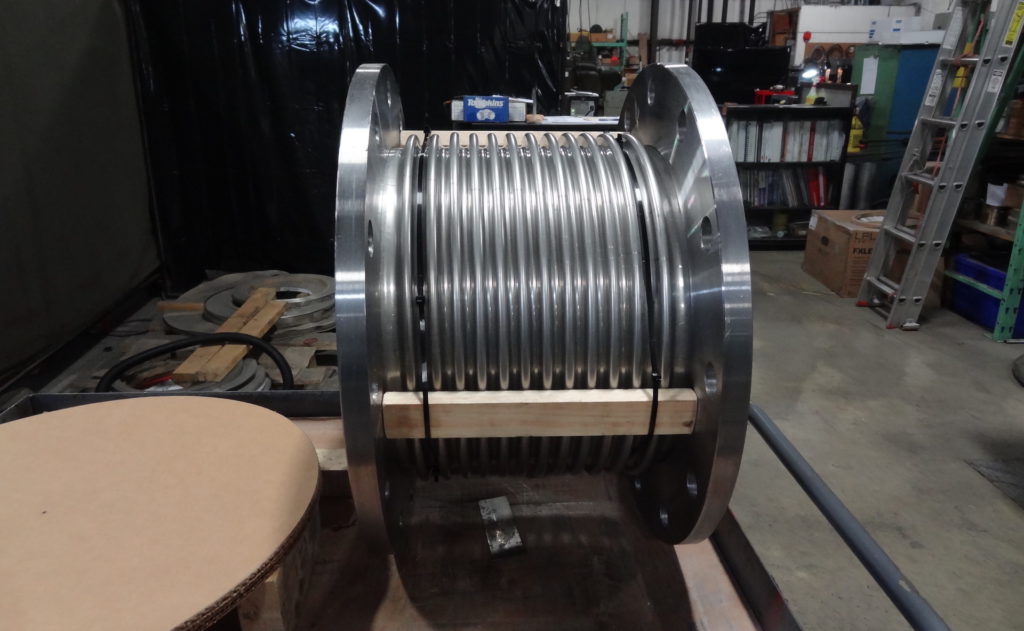

Expansion joints for water cooler ducts are designed for low pressure and low spring rates with high flexibility. These components damp vibration.

Steel mills rely on a range of metal hoses and expansion joints for successful operation. Penflex Sales Engineers are always available to help define application requirements for your next project, replacement, or repair. Beyond engineering and design support, we offer resources to support proper installation and maintenance for longer life in service.

To print this information, please click here.