Refinery Turnaround Hoses

Note: To print this page turnaround hoses, please click here.

Turnarounds are more than a routine maintenance event. The pause in production and significant costs for labor, equipment and materials make them a very expensive whole-business event, one that impacts a refinery’s workforce, its customers, and even its shareholders.

Every project has its own characteristics which makes each one a challenge.

While a poorly executed turnaround can be a major setback for a refinery, one that is well-executed can mean competitive advantage, increased commercial performance, improved operations and safety, and heightened morale. The stakes are high.

Turnaround Hoses

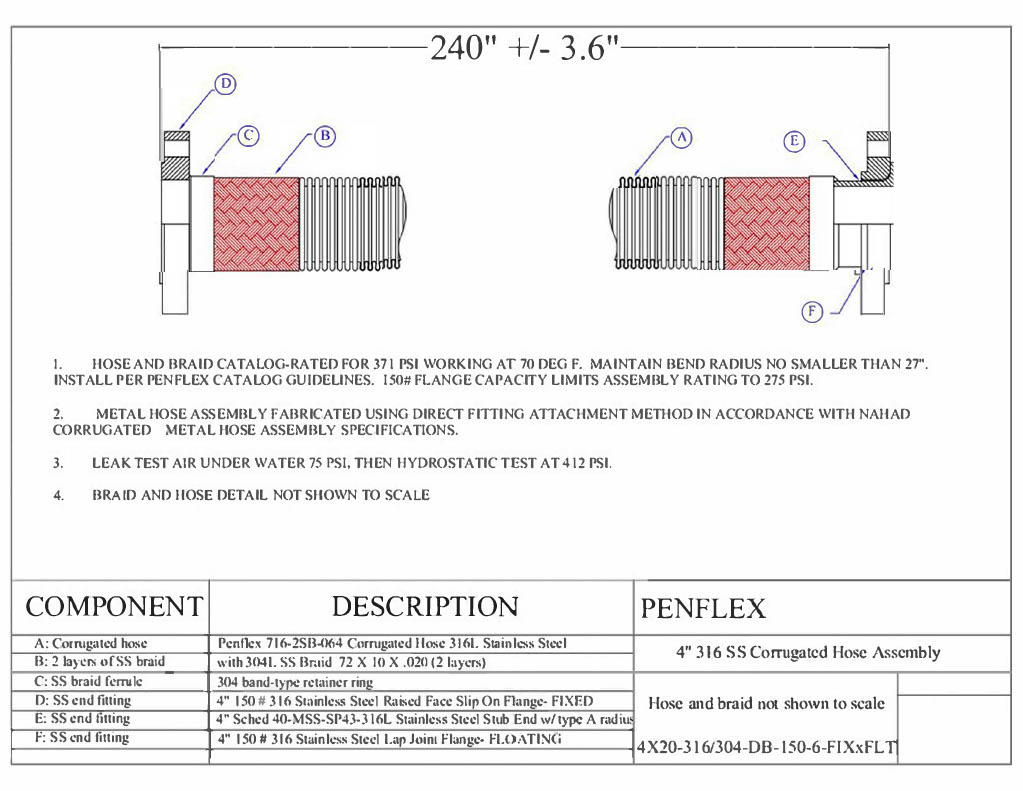

Understanding the mission-critical role metal hose plays in these events, Penflex designs and manufacturers assemblies to provide safe, durable and corrosion resistant options for refineries and turnaround operators.

Our hoses are often used as hydrocarbon drain lines, but other common applications include steam injection lines, transfer lines from storage tanks and vessels, and temporary bypass piping. In short, they are used anytime highly corrosive media needs to be transferred.

With contractors onsite and employees performing tasks outside their usual scope, safety is a top priority during turnarounds. And while the market is moving away from rubber hoses given the likelihood of catastrophic failure decreases when using metal, metal offers the additional benefits of corrosion resistance, the ability to work at higher temperatures, and overall durability.

Key Benefits

To ensure a longer life in service, Penflex turnaround hoses incorporate these characteristics.

- Heavy wall. Our line of heavy wall hoses offers greater corrosion resistance than do standard duty metal hoses, especially in areas where aggressive chemicals are being used.

- Double braid. In addition to increasing the working pressure of a hose, the second braid layer protects the first. It’s a proactive approach given how hoses are handled during turnarounds.

- Purging of welds. Argon purging of welds ensures clean, contamination-free welds. With numerous chemicals involved in turnaround operations, this approach delays corrosion.

Other key characteristics include:

- Lightweight. Our hoses are easy to move throughout turnaround operations and workers are less likely to hurt their backs in the process.

- Pressure rated Type A stub ends. While many of our competitors use non-pressure rated Type C stub ends, we use pressure rated Type A stub ends.

- Tested to 1.5x working pressure. Penflex uses conservative working and burst pressures for our metal hoses.

With a focus on safety, durability and corrosion resistance, Penflex offers a complete range of metal hoses with options for wall thickness, flexibility and pressure ratings to provide the ideal solution for a refinery’s unique turnaround needs.

To print, please click here.