Safety Relief Valve Vent Connectors

A safety relief valve controls pressure in a piping system, opening to release flow media when system pressure exceeds set design limits and closing once system pressure returns to within a safe range of operation.

Over pressurization can damage piping and equipment and interrupt production while escaping steam presents a safety risk.

Installed at the outlet end of a safety relief valve, vent connectors absorb vibration caused by escaping steam. They also accommodate thermal movements and help to further protect surrounding piping from damage.

Drip pan elbows are also used in this capacity, but they present the risk of steam blowback. Being fully sealed, expansion joint vent connectors are a safer option.

Penflex’s unique M-100 Expansion Joints have been used within the power industry as vent connectors for more than 50 years. With hundreds of successful installations, they boast a long record of success.

In more recent years, with the addition of metal bellows production capabilities, Penflex expanded its vent connector offering with more design options.

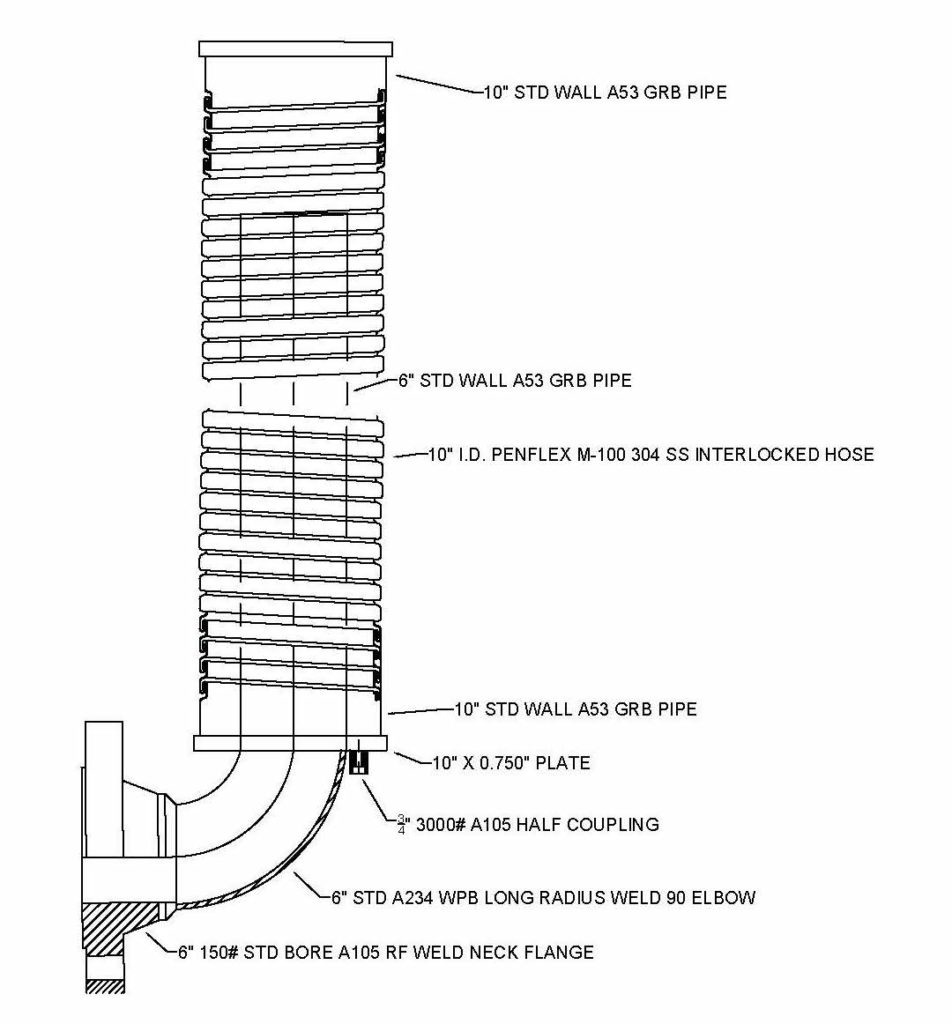

M-100 Vent Connectors

Penflex M-100 is a high quality, heavy duty, fully interlocked metal hose. The inclusion of packing into a specially formed groove during the manufacturing process serves as a continuous gasket to make the hose pressure tight. It’s the only hose of its kind in the world.

The sliding action inherent in interlocked hoses allows expansion joints made with M-100 to compress and extend axially and to deflect laterally. They can absorb these movements in combination as well. Even under considerable force following an expansion cycle, M-100 vent connectors prevent residual loading on associated piping and equipment.

Made with 304 Stainless Steel, M-100 vent connectors range in size from 2”- 24.” A number of horizontal and vertical configurations with various end fittings are available.

When there is a requirement for pressure rated expansion joints, M-100 vent connectors feature Penflex’s Tite-Pak flanged ends. When slight leakage is acceptable, M-100 vent connectors are available with butt-weld pipe ends, flanged, or slip over cuff ends.

These vent connectors are often supplied with reducing fittings on the inlet end to accomplish a reduction in the stack size to the valve outlet size. Straight sizes throughout are available as well.

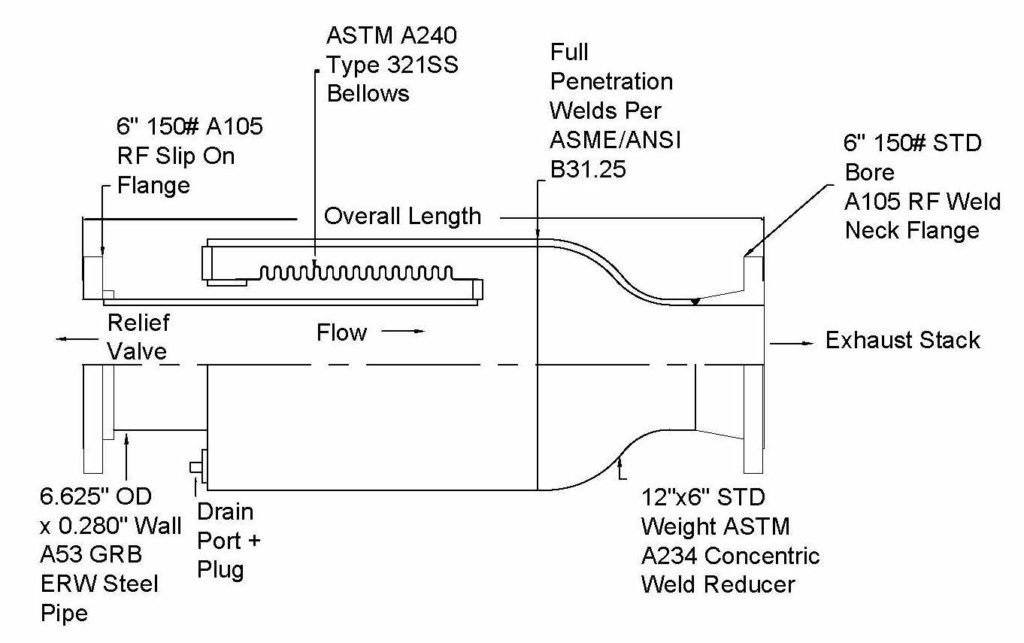

Metal Bellows Vent Connectors

Penflex bellows use principals similar to M-100 hose, taking advantage of the inherent all-welded construction to ensure completely enclosed and watertight vent connectors. Like the M-100 style components, those made with bellows accommodate axial extension and compression and lateral deflection. They are available in horizontal and vertical configurations and in sizes ranging 2”- 12.”

These vent connectors typically feature 321 Stainless Steel bellows and carbon steel housing and flanged connections. When corrosion is a possibility, other alloys such as Inconel 625 are available upon request.

Using bellows for the flexible compensator allows Penflex Sales Engineers to calculate cycle life according to the latest EJMA standards. The design engineer or plant maintenance lead associated with the piping system then has the ability to approve both the drawings and calculations associated with their vent connectors.

Bellows-style vent connectors also differ from their M-100 counterparts in that they provide superior vibration damping.

Custom Safety Relief Valve Vent Connectors

Typical vent connector designs allow for up to two inches of in-plane lateral and axial movement. However, a Penflex Sales Engineer can design for any situation, taking into account all design considerations while maintaining a special focus on pressure thrust and spring forces.

Regardless of design, all safety relief valve vent connectors require proper installation and anchoring.

To print this information, please click here.